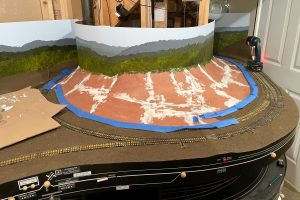

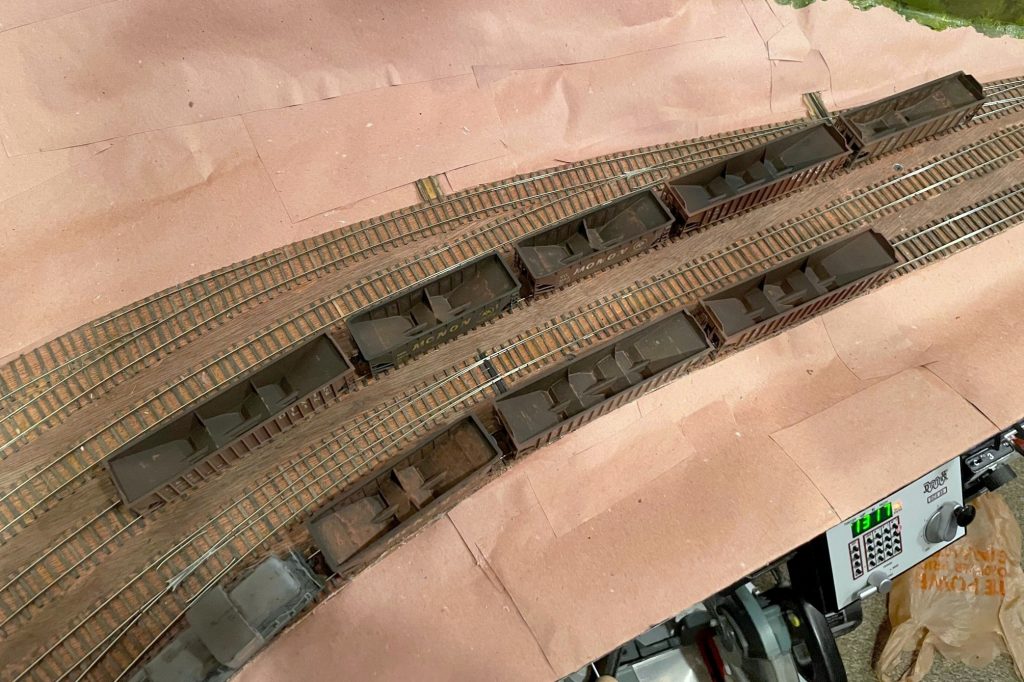

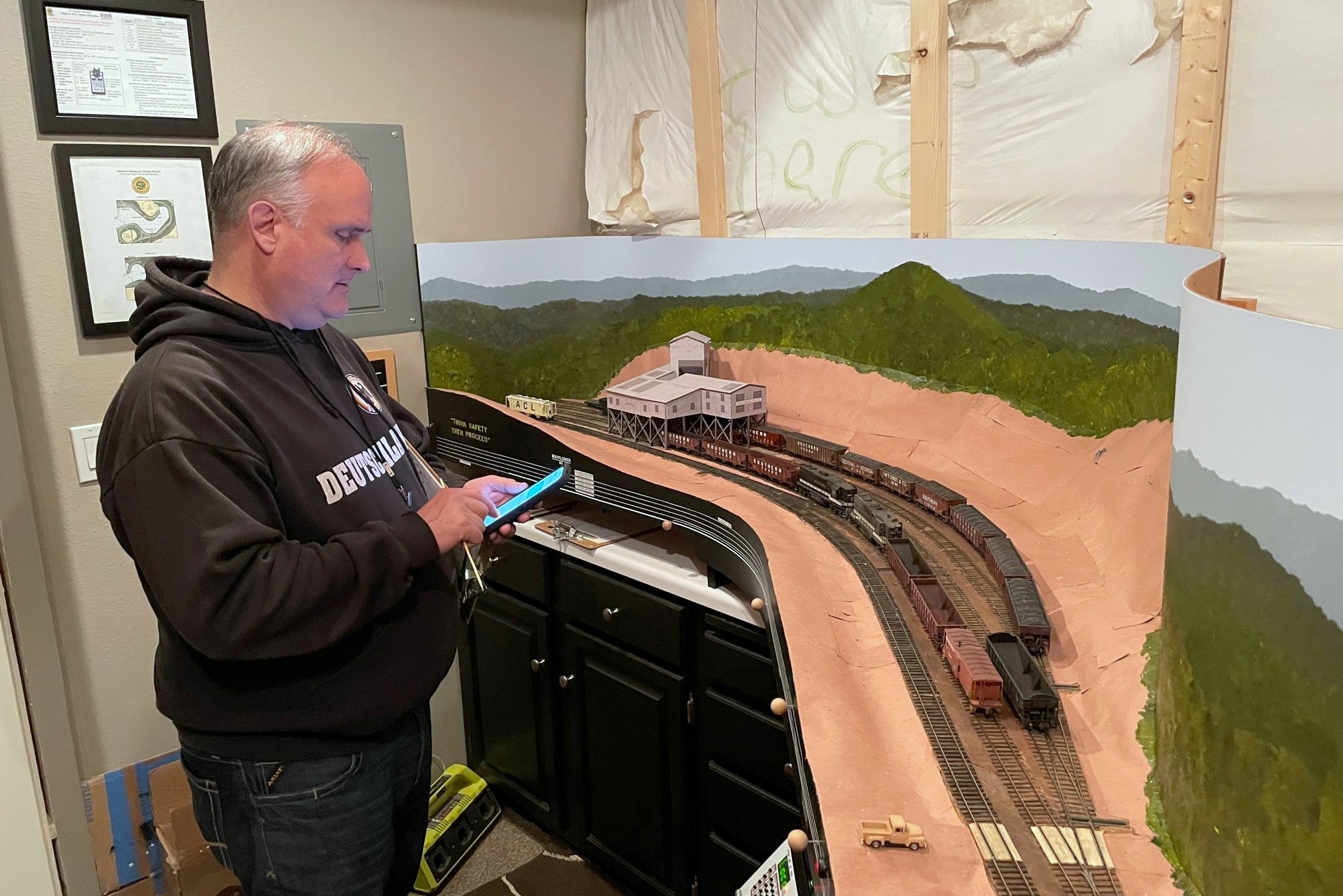

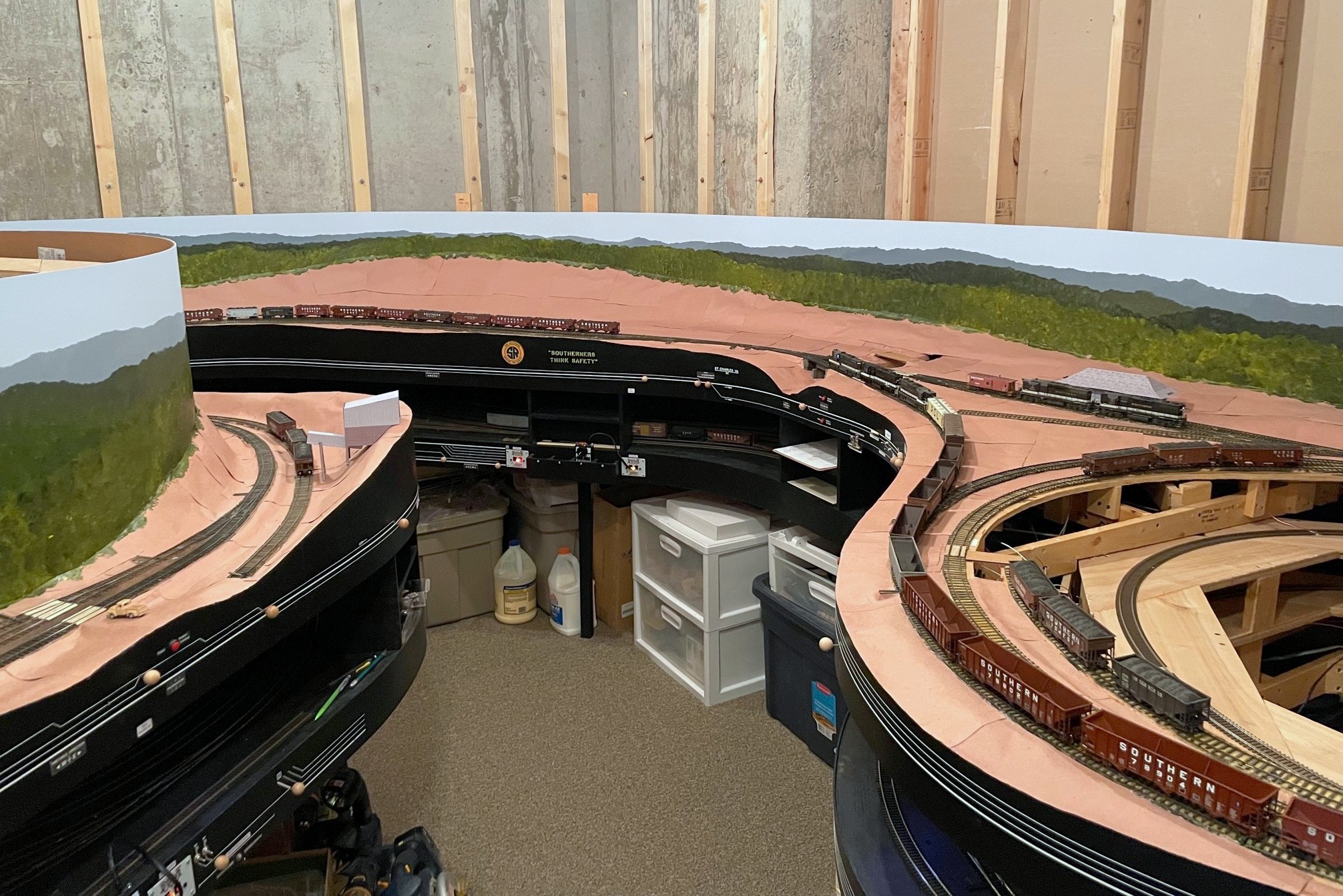

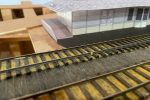

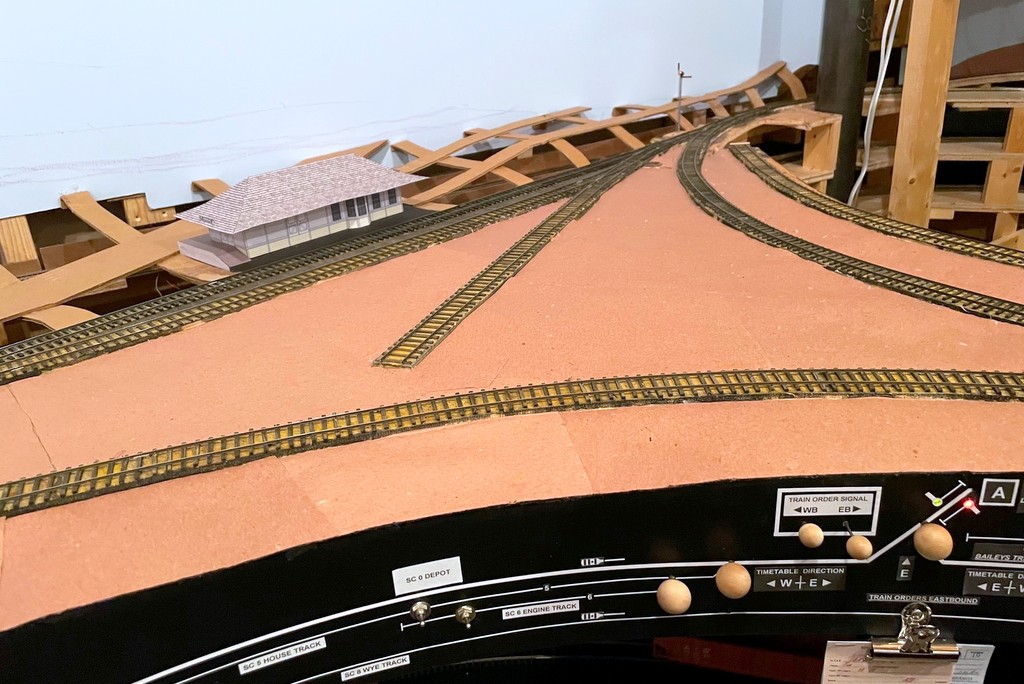

While I finished the basic scenery forms on the lower deck a few weeks ago, I decided it would be better to ballast the tracks before adding the upper deck benchwork while I still had good access to them. I’m so glad I did because ballasting gives the scenes a much more “finished” look even though there’s still a ton of scenery work to be done. I’ll be honest, I was dreading ballasting the track–I had little experience with ballast, but from that experience I saw it as a frustrating, tedious, and time-consuming job. I have now changed my tune! While it’s still time-consuming, I was able to learn and mature my techniques quickly to avoid the frustration and tedium, so I’ll pass along my method here.

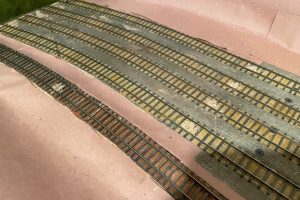

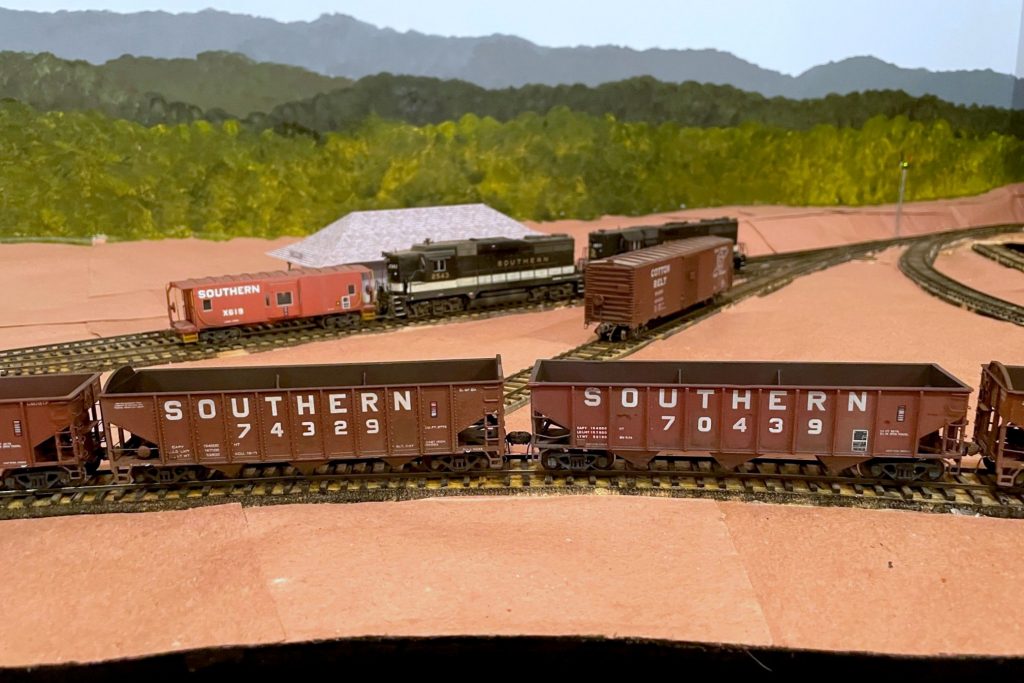

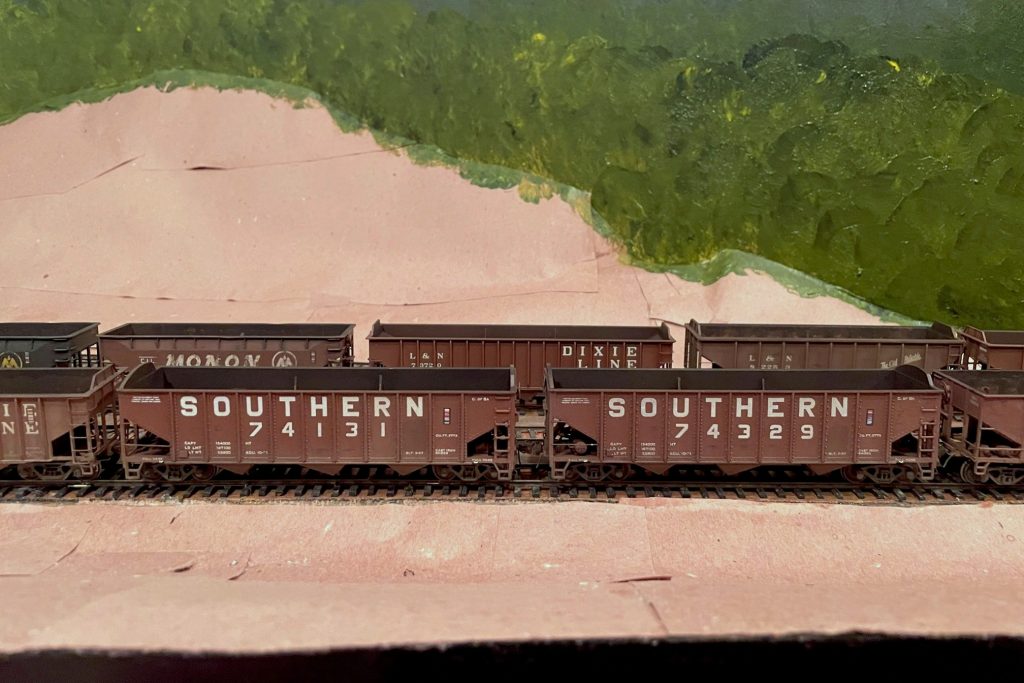

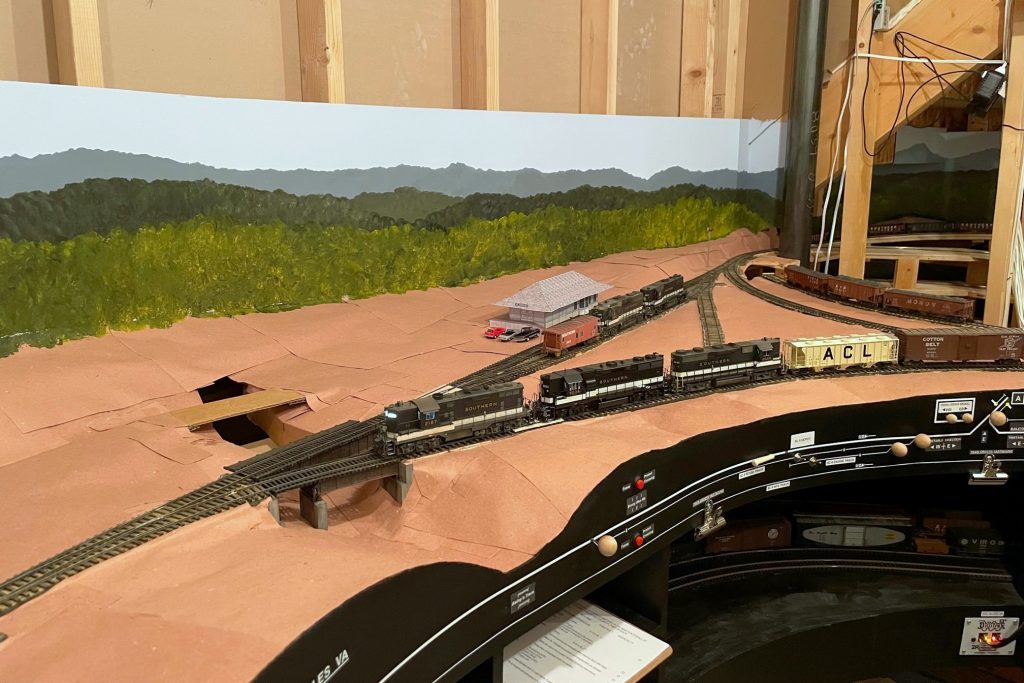

First, I had to determine what kind of ballast I needed. This wasn’t as straightforward as I’d hoped. As best I can tell, most of the tracks in my area were at one time ballasted in cinders harvested from steam locomotives. The steam locos went away in the 1950s, and with them the ability to get cheap and ready cinders for ballast. Photos from the ’80s and ’90s clearly indicate most everything got covered in rock ballast–would the cinders still be around in the 1960s and ’70s? After some digging online, I found that cinders in many places lasted for decades after steam, and in the coal fields, it’s tough to tell cinders from spilled coal anyway, so an added incentive for cinders, at least on sidings and secondary tracks. For the main tracks, photos show the Southern’s ballast in this area was a medium gray. I toyed around with trying to find some actual rock to use as ballast, but in the end I decided on good old Woodland Scenics products made from crushed walnut shells because I can find it readily, it doesn’t cost an arm and leg to ship, and it’s pretty easy to work with. I used fine cinders and medium sized gray ballast in the big shaker containers for this project, and I was able to do the entire lower deck (12′ x 16′) with just under two shakers of each color (4 shakers total).

Second, I did a bunch of research on how to apply ballast, and I am so glad I did! In the end, I went mostly with the method Cody Grivno of Model Railroader lays out in the article here. The only other materials I needed were white glue (I bought a gallon), isopropyl alcohol (I used about XX oz), and dish soap. For tools, I used a spoon, a large flat brush, a white glue dispenser (like the ones kids use in school), two small jars with eyedroppers, a work glove, and my fingers. In the glue bottle, I mixed up some “just a bit wet glue” which is about 2 parts white glue, 1 part water, and a drop or two of dish soap–when you squirt it out, it should dissipate from its bead but not run. In one of the jars with an eyedropper, I made a mix of “very wet glue” of about 1 part glue, 6 parts water, and a drop or two of dish soap–it should look about the consistency of milk and absorb into the wet ballast (I’ll explain that in a minute) after a few seconds. You’ll need a LOT of the very wet glue, so you can either make a big batch or mix it on-demand when you run out (what I did… it was a lot of trips). The remaining jar and eyedropper are for the isopropyl alcohol.

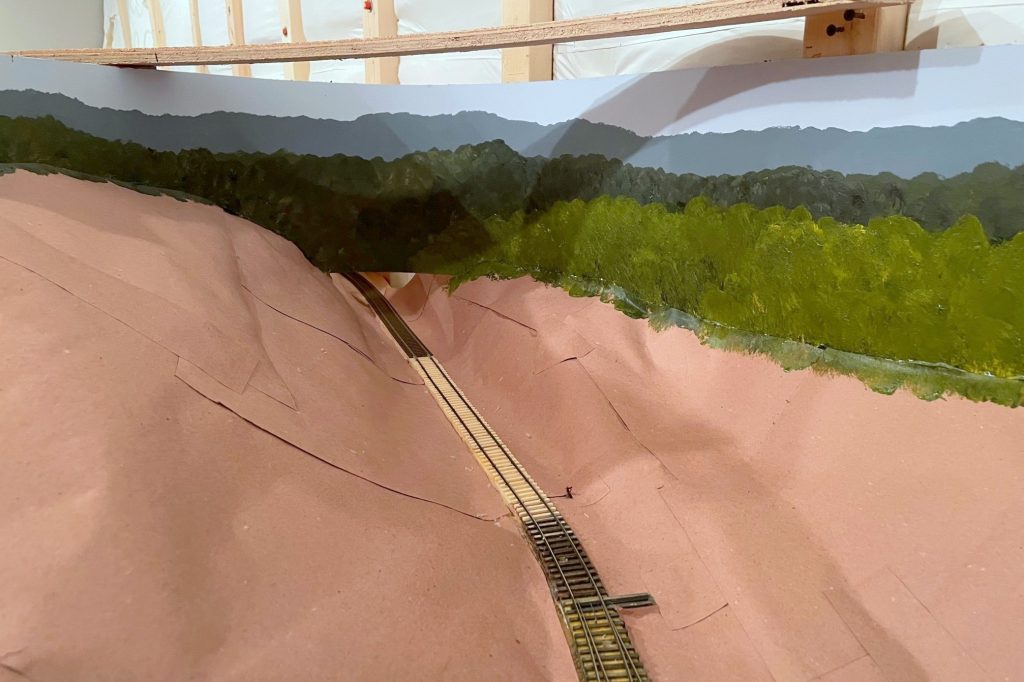

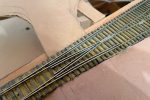

I worked on the track in about 2 foot sections, usually one track at a time. If you’re doing two ballast colors, determine which ballast should be “lower” and work on that one first–for me, the cinders were replaced by ballast rock, so where they overlap, I did the cinders first. With about half-a-spoonful of ballast, I first apply it to the “gauge” (inside the rails) of the track. It takes a few tries to get a feel for how thick to lay it, but it becomes routine pretty quick. You want just enough that when you spread it the ballast fills the space in between the ties and rails with little on top of the ties and nothing on the rails. I found my finger to be an effective spreading tool, and I just rub it back and forth down the tracks, rubbing any excess ballast to open areas. Cody glues his ballast at this point, but I found it easier to lay the edge ballast first. I applied ballast to the edges by first running a bead of glue from the bottle down the side of the subroadbed and on top of the scenery–this helps the “slope” to hold better. Next I used the spoon to apply ballast inward toward the rail from about the edge of the ties until I couldn’t see the edge of the subroadbed any more. I used my finger again, first to poke the ballast under the rail a bit, then to wipe off the tops of the tie edges, and then to pat down the sloped edges until they looked smooth. I used a brush to clear off any unwanted ballast to outside the range of the glue (I vacuum it up later) and to remove any stubborn ballast from areas my finger couldn’t get to.

Once I’m happy with the ballast shape, I glue it down. The critical part of this process is to USE THE ALCOHOL AS A WETTING AGENT FIRST! If you just add the glue, the ballast will float (and float away) which makes a frustrating mess. You can avoid this by first saturating the ballast with an eyedropper of isopropyl alcohol–just drop until everything looks wet. I follow the alcohol wetting with the very wet glue, making sure I apply drops to every section of ballast until things were saturated and it took a couple seconds for the glue to soak in. If you drop a big glob of white glue that somehow didn’t get diluted, no worries–just dilute it with some alcohol, and it will likely settle in just fine. I wet and glued each section by starting with the gauge between the rails, then moving to the edges. I found for the edges it’s better to start the alcohol low and work up to keep things in place, and its better to start the glue high and let it work down.

Turnouts require a bit more care, and I probably didn’t take all the care I should have… it worked out ok, but I spent a couple hours massaging my turnouts to get them working smoothly again. I spread the ballast a little less thickly between the ties to make sure the points wouldn’t catch, and I took care to avoid putting ballast in the area of the throw. No matter how careful I was, there was always some piece determined to get stuck in the throw, so I used the brush (and the occasional X-Acto blade) to fish out any offenders. I used the very wet glue sparingly in these areas, but there was still some glue that stuck to the top of the ties causing the points to stick a bit. I believe Cody’s method is to drop the glue in first, then add the ballast under the points, and I think I’ll try this next time.

After letting the glue dry overnight, I clean up any excess ballast. First, I use a work glove and rub it over the top of the ties and edges to knock off any obtrusive pieces. Next, I clean out the area in the web (sides) of the rail using a matchstick rubbed back-and-forth followed by a fingernail. I used a flathead screwdriver to clean out flangeways if necessary. I cleaned up any excess with a vacuum. You’ll inevitably find spots you missed with the glue, but it’s easy to just add more ballast, drop some alcohol, then drop some glue to repair.

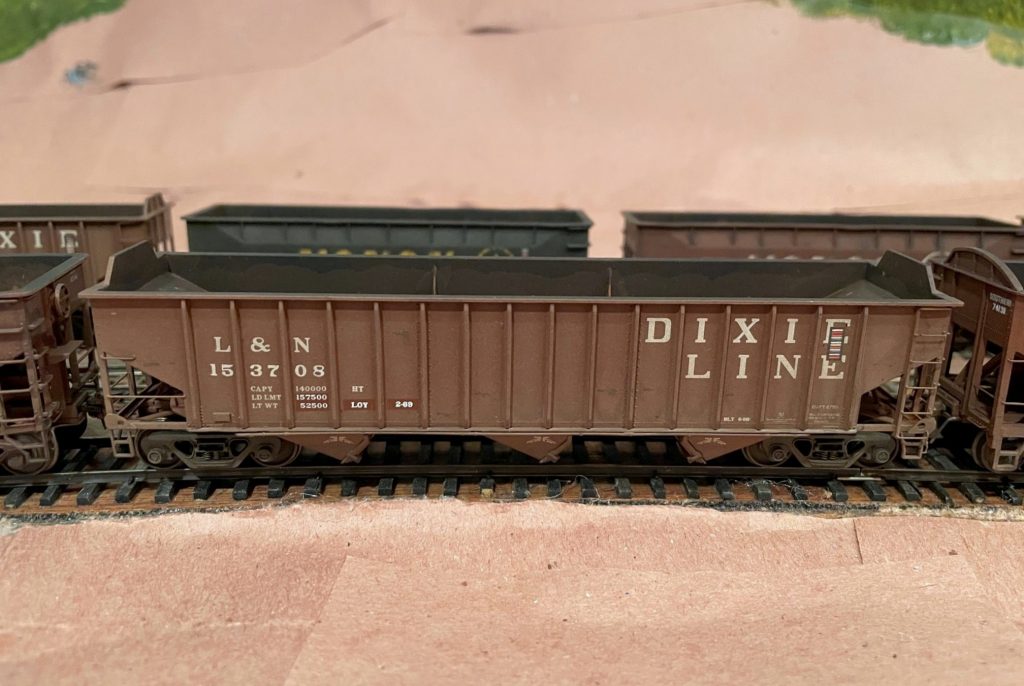

Ballast is scenery, so I also wanted it to tell a story. Because track repairs would have been made with gravel instead of cinders in my era, I picked a few spots along the cinder-ballasted yard tracks to fill with gravel (in this case, Woodland Scenics fine gray ballast) to simulate a replaced tie. I like the look! I also picked a few spots in prominent areas to lay some cinders on the scenery to go underneath the ballast rocks to show that some tracks were once cinders but had now been ballasted with rock. I also laid a thin layer of cinders in areas where I know tracks used to be, even though I don’t model them in my era. Finally, I added extra cinders to areas under tipple chutes and where locomotives sit to represent spilled coal and grime. I’m pretty happy with how these “extras” turned out, but they won’t fully tell the story until more scenery is complete.

Ok, the ballasting was the last step before adding the upper deck, but you’ve heard that before… We shall see.