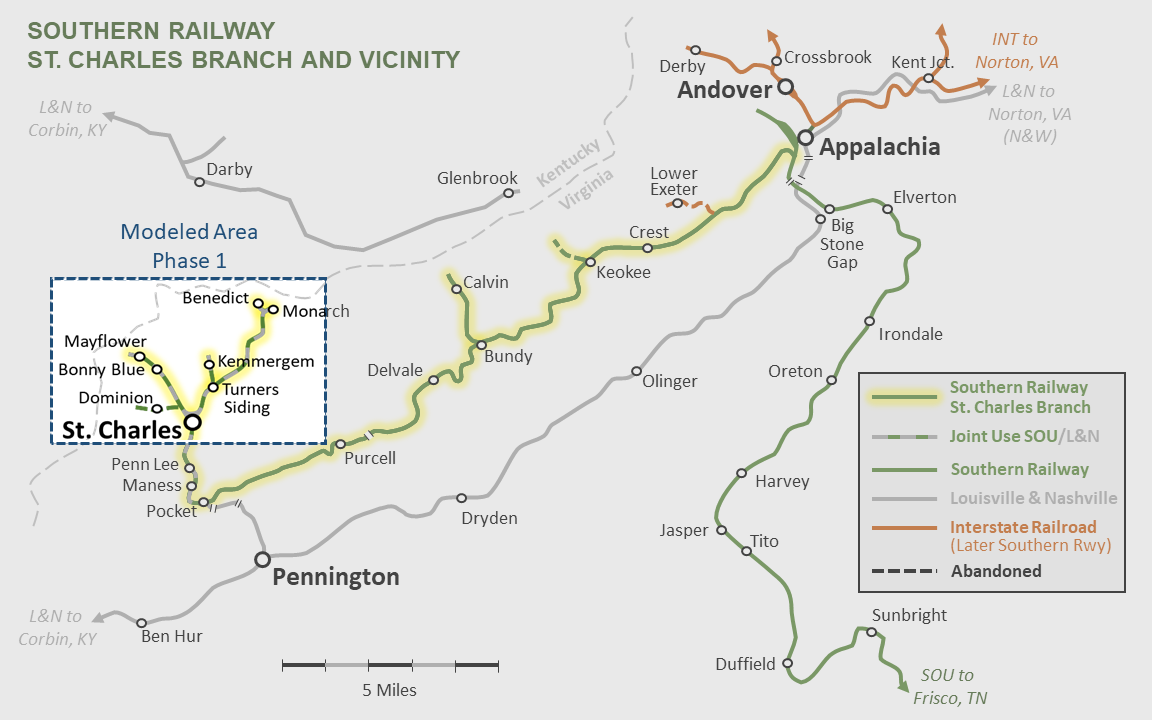

- Prototype Map

- Era

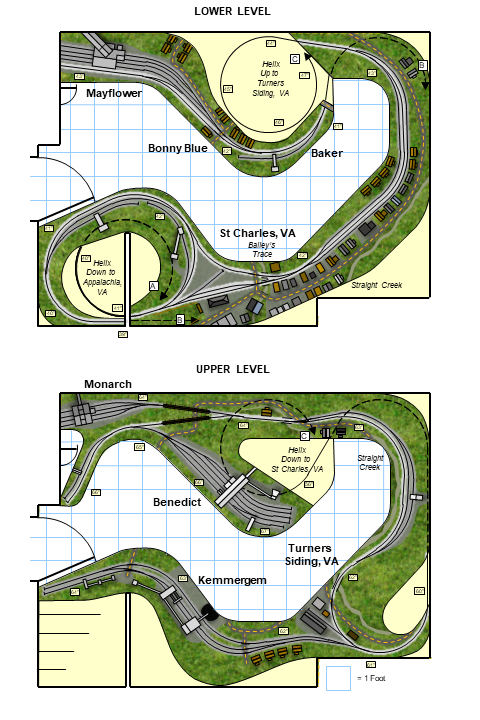

- Track Plan

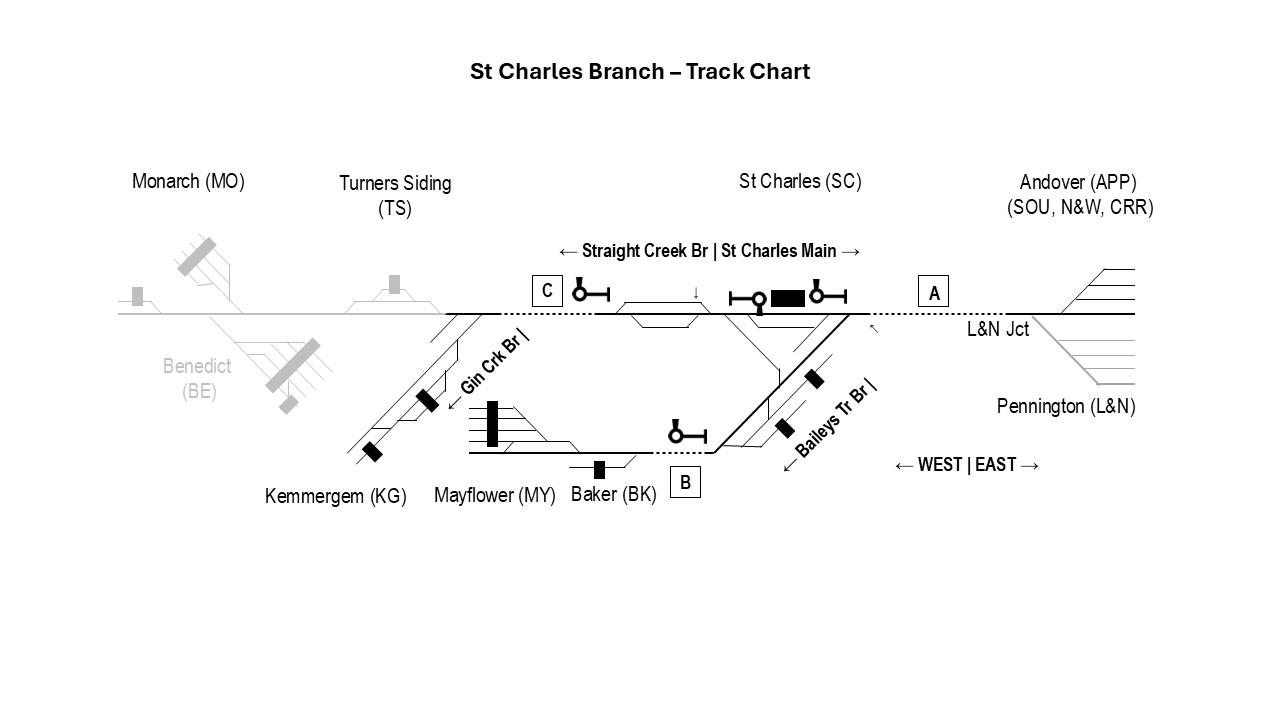

- Track Chart

- Train Protection

- Fast Clock

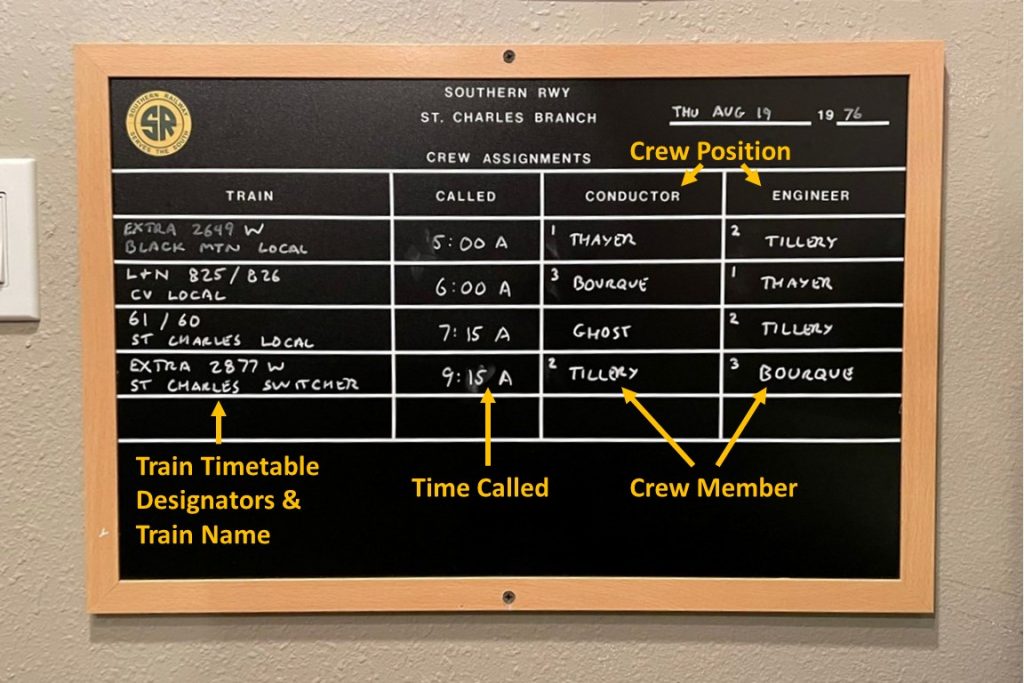

- Crew Assignment Board

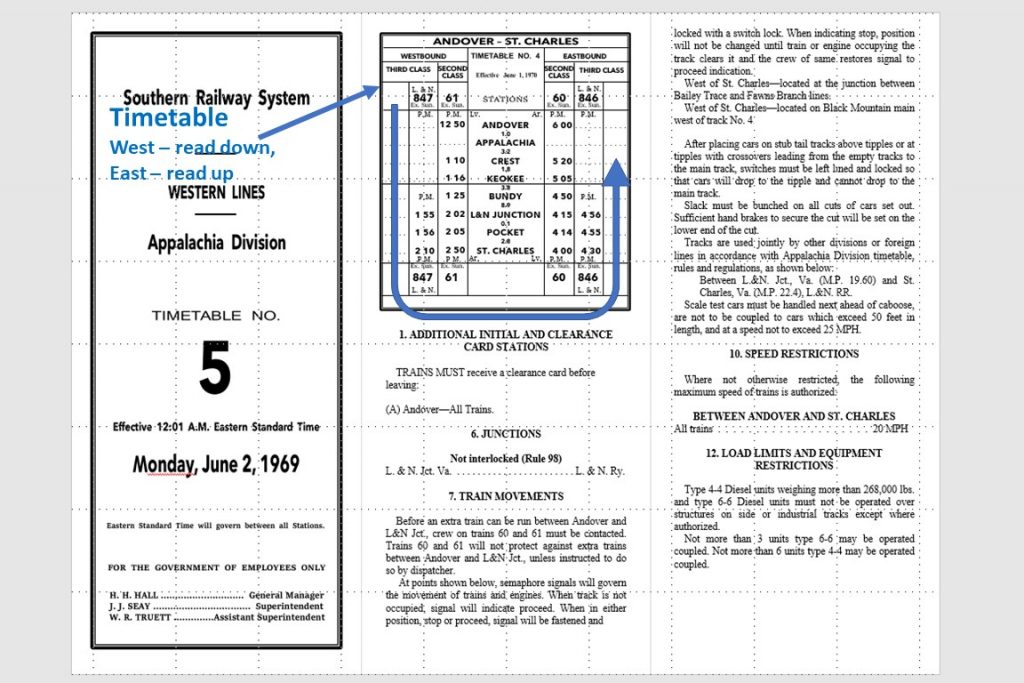

- Timetable and Train Orders

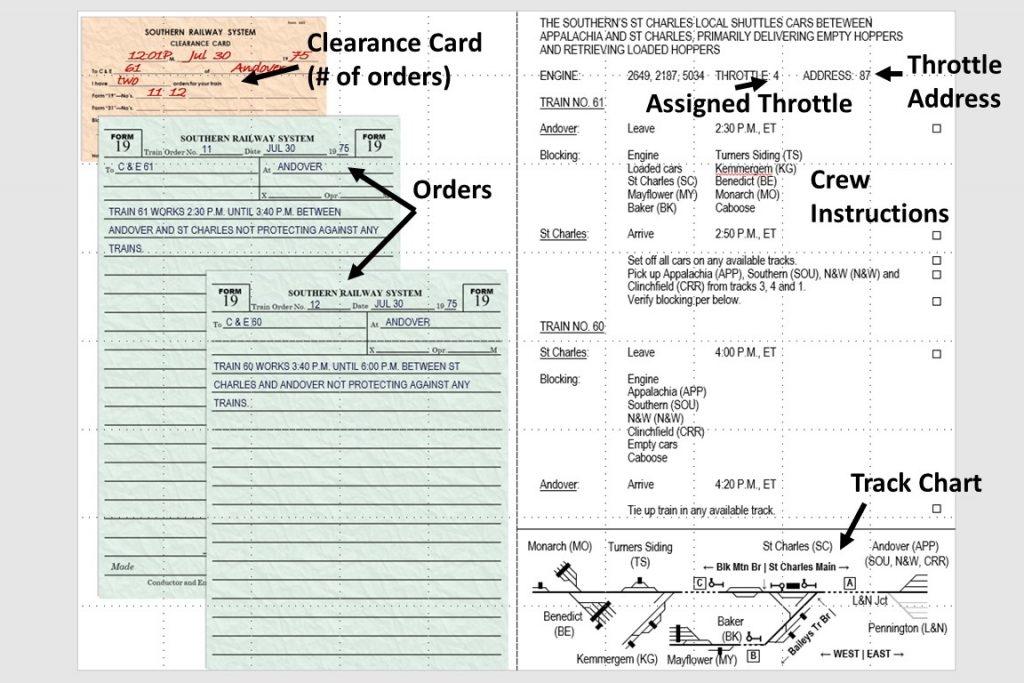

- Conductor Responsibilities

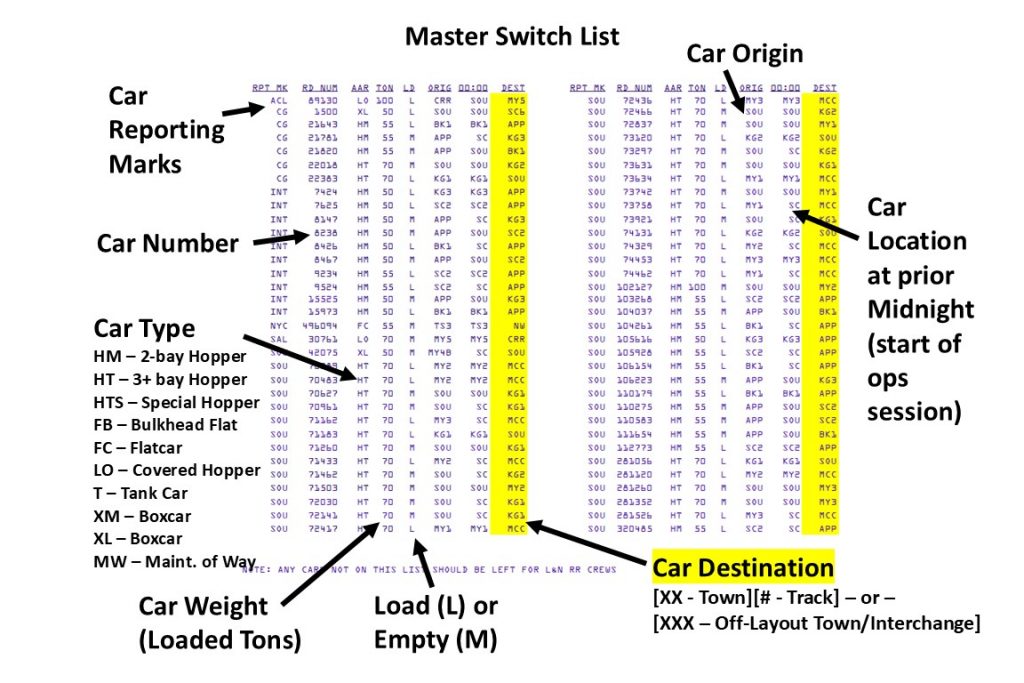

- Switch List

- Engineer Responsibilities

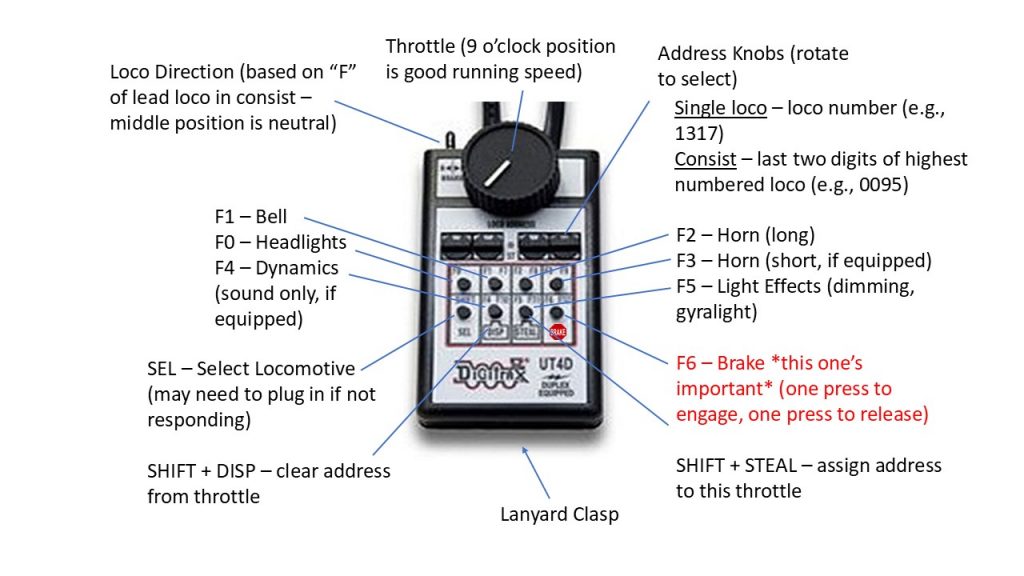

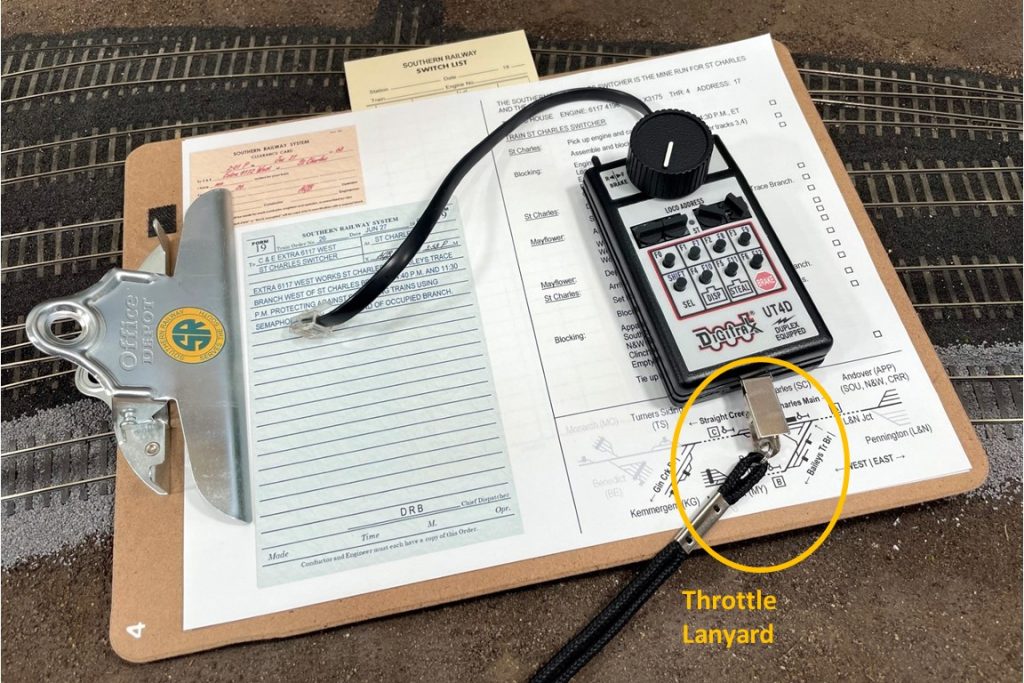

- Throttles

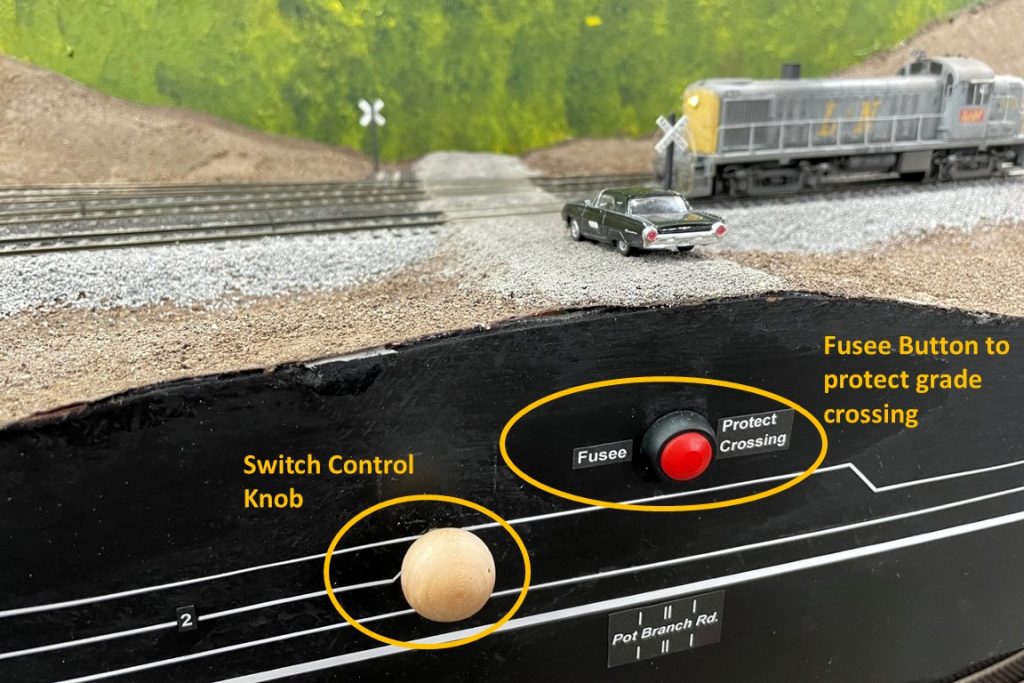

- Fusees to Protect Crossings

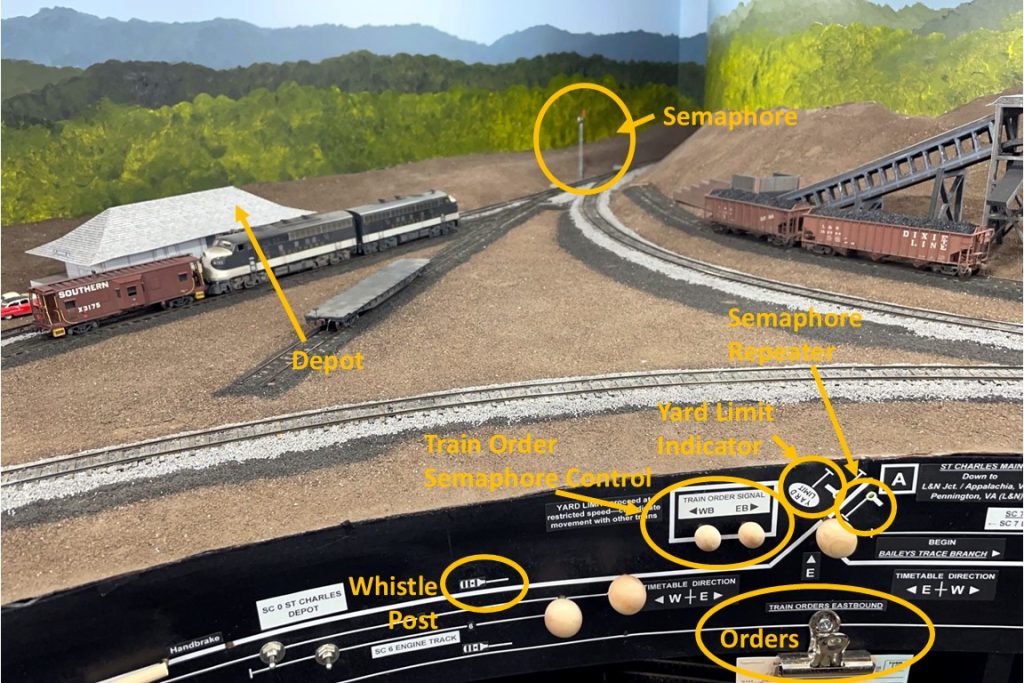

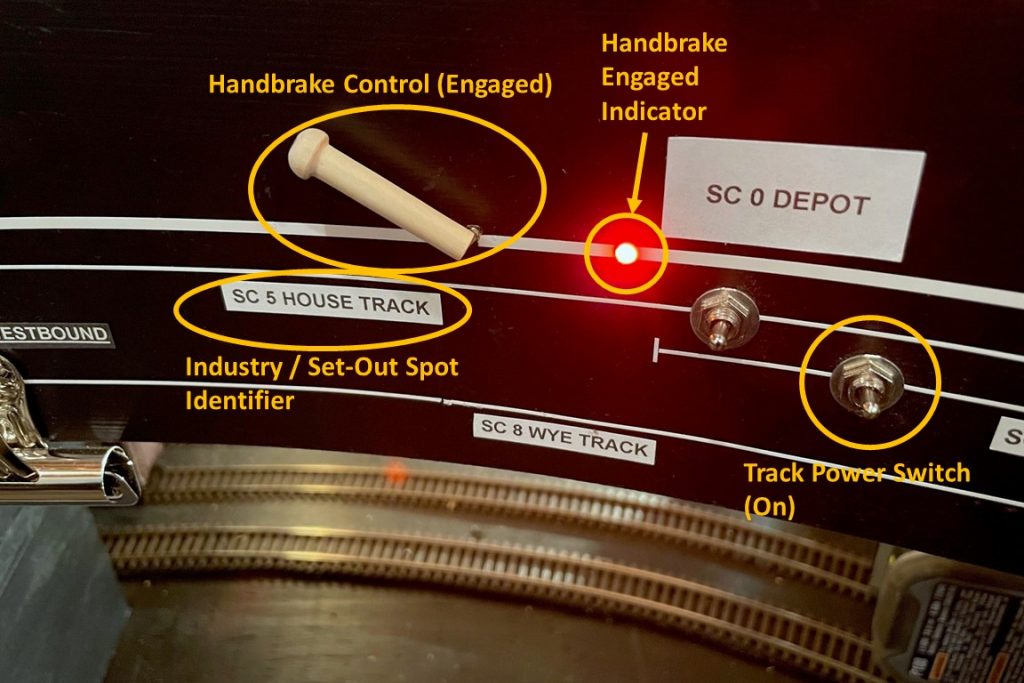

- Fascia Controls and Labels

- Additional Tools and Tips

- Hints for Working the Layout

Welcome to the hollers of southwestern Virginia, home to the Southern Railway’s St. Charles Branch on the Appalachia Division! Here are a few things to help you survive your first day on the job. First off, we do things slow and deliberate ’round here. The coal will be here tomorrow, so no need to rush and do things dangerous-like. We’re all friends in these parts, so a little jawin’ and talkin’ is part of the job. If you get too focused that you can’t say hello to your fellow railroaders, you’re takin’ things a bit too serious.

The St. Charles Branch exists for one reason: to haul coal from the hollers of Virginia along Little Black Mountain and the Kentucky border to feed the larger markets served by the Southern Railway and others. The branch extends west from Appalachia, Virginia to St. Charles where it divides into several branches, each dotted with multiple coal tipples of various sizes and configurations. The Southern stations a mine crew (often two) in St. Charles to work these branches which is the focus of the layout’s operations. These mine runs are called the “St Charles Switcher” or the “Black Mountain Local.” The Southern has a scheduled train, train 60/61, that shuttles coal hoppers between Appalachia and St. Charles, feeding empties into the small yard for the mine runs and picking up loads bound for points east. After 1965, coal originating on the branch is divided into two main categories, customer coal and transloader coal bound for the huge Westmoreland Coal mixing and transloading facility in Appalachia, Virginia. Cars reflect these two categories in the ’60s and ’70s with newer 70- and 100-ton hoppers, often called “reds,” handling customer coal and older 50 ton hoppers on their last legs, known as “blacks” or “yellow balls,” handling the transloader coal.

The Southern’s fierce competitor and neighbor, the Louisville and Nashville Railroad (L&N) has trackage rights over the entire modeled portion of the branch allowing it to serve the tipples in the area from its connection from the L&N mainline at Pennington, Virginia to a junction with the Southern at Pocket, Virginia (L&N Junction). L&N trains usually only work the line three times a week with a small train known as the “Cumberland Valley Local” (CV Local) after the L&N subdivision on which it originated. The CV Local runs from its home base of Corbin one day, overnights in Pennington, and works the St Charles Branch the next day.

The St Charles Branch layout covers multiple eras from about 1963-1977, but each ops session will only cover a single year. The number of trains and cars and the schedule varies by year, so it’s good to know where you fall. The eras break down into a few distinct time segments:

- 1963-1964. This era is before the Southern took over operations of the nearby Interstate Railroad and its cream, orange, and gray RS3s. The Southern had purchased the Interstate a few years prior, but operations were still separate, though cooperative. The Southern’s main yard for the St Charles Branch is in Appalachia, Virginia. Operations are pretty slow, especially for the L&N which only runs a few times a week. A variety of black or gray paint schemes can still be spotted on the L&N’s RS3s that work this area. On the Southern side, motive power is mainly F-units with the occasional GP7. Cabooses are red except for a few of the newly repainted cabs in the “Brosnan Brown” scheme. The Southern has also introduced some new larger cars like the 100-ton “silverside” gondolas that occasionally load on the St Charles Branch. The original operators of the big tipples are mostly still in business, though things are pretty slow, and the company towns are being sold off in quick fashion.

- 1965-1969. In 1965, the Southern consolidated its yard with the Interstate’s yard at Andover, Virginia, and the bright RS3s left Virginia rails never to return, replaced by the same old F-units the Southern crews use for the St Charles Branch. The cabooses are almost all brown now, and the L&N’s classy black and cream RS3s are exceedingly rare, replaced with the spartan black scheme or a newer gray and yellow repaint if you’re lucky. Coal operations are shifting from the big tipples to more truck-dump style operations hauling in coal from local strip mines via trucks–many of the classic tipples have been converted to truck dumps. The Interstate influence is much more apparent as the railroad’s fleet of a few thousand twin hoppers has been converted to shuttle cars (“yellow balls”), and the small yellow dots on the sides designate many of these cars as local service only. They’re shuttle cars for the new transloader facility built on top of the old Southern yard at Appalachia, and coal from all these outlying tipples – to include a few tipples on the St Charles Branch – is sorted, cleaned, stored, and blended before being loaded in one of several unit trains now feeding the growing power needs of the South. The transloader has also eliminated the loading of silverside gons on the branches as these are now exclusively dedicated to unit trains.

- 1970-1973. In 1969, the Southern collected all the F-units and replaced them with GP38s practically overnight. The Southern also began a major caboose rebuilding program, thankfully resulting in cabooses being painted their proper red color again. This is the last hurrah for the L&N’s tired RS3s, though coal traffic is beginning to creep up a little for both railroads. A few new tipples – all truck dumps – have been built along the branches and the line between Appalachia and St Charles. “Yellow ball” shuttle cars are still prominent, though the original Interstate cars are getting tougher to find, replaced by a fleet of hodgepodge rebuilt twins from the Southern and predecessor lines like the Central of Georgia.

- 1974-1977. The coal boom is in full swing thanks to the energy crisis, and the St Charles Branch is no exception! The Southern has augmented the GP38s and GP38-2s with some older turbo units like GP30s and GP35s, and the trains are getting longer. Many cabooses now sport attractive large patches of yellow on the bays or cupolas denoting them as “local service” cabs. The L&N has replaced its ancient RS3s with C420s, though only the ex-Tennessee Central units, 1316 and 1317, are used on the CV Local due to weight restrictions. Toward the end of this era, the L&N stations a pair of old Alcos at Pennington to handle the now abundant tonnage coming from the St Charles area. The hopper fleet hasn’t changed much, though with the introduction of more 100-ton cars, the 70-ton cars that have been the staple of single-car loadings are starting to replace the twin hoppers in “yellow ball” service. The Southern’s hopper fleet also now includes hoppers from a few newly acquired roads such as the original Norfolk Southern and the Tennesse, Alabama & Georgia.

- 1978. The classic wooden depot at St Charles burned down, the L&N started painting things in “Family Lines,” and all the 50- and 70-ton cars got those dang U-1 wheel inspection dots… this is why I don’t model past ’77.

Here’s the track plan for reference. Trains come up from staging (Appalachia/Andover and Pennington) to St Charles. Two branches extend from St Charles. The Bailey’s Trace Branch to Mayflower extends behind the scenery to emerge at Baker on the lower deck. The Straight Creek Branch heads up the helix and emerges at Turners Siding where it splits into the Straight Creek Branch to Benedict and the Gin Creek Branch to Kemmergem.

Here’s a functional track chart to help identify where the tracks go and where the towns lie.

The St. Charles Branch is “dark” territory and is operated via Timetable and Train Orders (TTO). Only Train 60/61 and L&N’s CV Local are on the timetable–all other trains, including the mine runs, are run as “extras.” Additionally, the entire modeled area for the town of St Charles is considered “yard limits”–crews should expect to meet other trains here and be able to stop within half the visual distance. There is no yardmaster to coordinate movements, so train crews meeting in St Charles move at restricted speed (able to stop in half the visual distance) and coordinate and deconflict movements among themselves. All other movement and operation is done in accordance with train orders, switchlists, timetable, and train instructions (all described later). Trains working the branches west of the yard limits at St Charles are protected by semaphores set by the crews (described in more detail later).

The St Charles branch uses a 3:1 fast clock. There are two analog fast clocks, one located above the door in the train room and one located in the crew lounge. Fast clock controls are located in a recessed panel on the fascia near Kemmergem on the upper deck. Crews will not normally need to use these controls, but the idea is to operate at a relaxed pace, so if the clock is making you cut corners or speed up too much, feel free to pause time for a bit by switching the fast clock off–just let your host know so we can get it running again when appropriate.

The crew assignment board is located just inside the door of the layout room on the left side. Most trains operate with two-person crews, a conductor and engineer, and you can expect to perform both duties in a normal operating session. The “Crew Assignment” board indicates the conductor and engineer (or the combined conductor/engineer) for each train and the time the train is called. There is no live dispatcher, but clearance cards and orders simulate the dispatcher’s role in keeping trains separated and performing their assigned work.

Every train must have at least a clearance card to proceed. The clearance card will list any orders that pertain to the train, its movements, and any timetable amendments. Both the Conductor and Engineer must review the clearance card, timetable, and any orders prior to proceeding. Crews must only occupy track authorized by either the orders or timetable. The timetable can be found on the back of the clipboard for each crew. A train not on the timetable will operate as an “extra.” Any extra trains working east of St Charles must have orders authorizing this movement and must clear mainline tracks and line switches for through movement on the mainline no later than 5 minutes prior to a scheduled train’s arrival unless in possession of orders to the contrary (there are currently no extra trains in an ops session that need to work east of St Charles). Trains authorized by the timetable will not arrive at stations earlier than the time listed on the timetable unless in possession of orders to the contrary. Extra crews working within St Charles yard limits must ensure the mainline tracks are clear for timetable arrivals until it is verified the scheduled train has passed. There is currently no train register–coordination with other crews will suffice for this verification. There is no yardmaster to coordinate movements, so train crews meeting in St Charles coordinate and deconflict movements among themselves.

Timetable trains end at St Charles and must receive train orders to proceed beyond the west yard limits at St Charles–all trains working west of St Charles (i.e., beyond the last station in the timetable) must have orders. The St Charles Depot serves as a train order station, and a tall semaphore at the junction of the St. Charles Branch and Baileys Trace Branch near the depot serves to signal trains to proceed (green), slow down for orders (amber) or stop and sign for orders (red) at the depot–there is a semaphore repeater on the fascia if the actual signal cannot be read. The small, three-track St. Charles Yard runs along both branches, and beyond the yard, each branch is protected by a dwarf semaphore which much be unlocked, set by the crew, and locked to protect trains heading up the branch per their orders. Crews should not proceed into the hidden trackage beyond these semaphores if they are set to red–running only motive power just beyond the last switch to complete a run-around move is allowed even when the semaphore is red.

You direct the movements of the train and the handling of cars. Once the time your train is called arrives (you won’t actually get a call), you’ll need to pick up the clipboard for your train from the desk near the door. Each clipboard contains a copy of your clearance card and train orders, train instructions, a master switch list, a blank switch list, and an Employee Time Table (ETT) on the back. Start with the instructions–they tell you about the train, tell you which locomotives and caboose are assigned to your train, and which throttle address to use. They also give you a run-down of what the train needs to do, to include blocking instructions for cars–if you pick up a train in staging, it will already be blocked, but for everything else, it’s YOUR job to make sure the cars are blocked properly, especially when it comes to placing all loads ahead of all empties to keep trains safe on the curves and steep grades. If you don’t have a feel for the layout of the towns on the line, there’s a track chart at the bottom of the instructions. Of note, not all tracks will be “active” for every session (tracks and loaders came and went over the years)

As the conductor, it’s your job to tell the engineer where to go, when to go, and where to set out and pick up cars to get them to the destinations in the switch list. Also, you ride in the caboose, so it’s also your job to serve as the rear brakeman lining switches, protecting crossings as needed, and calling out instructions and distances to the engineer for set-outs and couplings (e.g., “bring it back 100 feet to a couple… 2 cars… 1 car… that’ll do”).

The next important piece of paperwork is the master switch list generated by one of them newfangled computer things. This master switch list has the reporting marks of every car on the layout along with its destination and is sorted first alphabetically by reporting marks then numerically by car numbers. There are also columns describing the car’s origin and its position at the midnight prior (start of the ops session), but the destination column (highlighted) is the most important. There is one list for the Southern and one list for the L&N. You can either use the list as-is, or you transcribe the reporting marks for just the cars in your train onto the blank switch list provided. Don’t get consumed with combing through the switch list–work the cars in front of you and use the switch list to inform your decisions on what to do with the cars.

At each town, the conductor checks to see which cars in the train need to be set out at local tracks and picked up from set-out tracks using the two-letter designation code for each town and numerical designator for each track. Three-letter designation codes are for cars heading to staging. For tipples, there is a “load side” (LD) and and “empty side” (MTY) based on gravity, so you’ll need to set off empty hoppers “above” the tipple and pick up loads “below.” For most mine runs, the standard methodology is to set out empties as you move up a branch line and pick up loads on the way back, but some track arrangements (e.g., trailing point moves) will necessitate dragging loads with you up the line if they’re in the way or there’s nowhere to set them aside or setting out empties on the way back.

You drive the train, following the train orders and instructions of the conductor. When the time your train is called arrives, you’ll need to meet up with your conductor to review your paperwork (or you’ll pick up your paperwork if you’re acting as both). The instructions will tell you which throttle to use, or at a minimum, which address and locomotives to use–the convention is the locomotive address for a single loco and the last two digits of the highest numbered loco for a consist. Each locomotive/consist is set up with a good bit of momentum, so you’ll have to plan your starts and stops carefully. You’ll also want to familiarize yourself with the brake–it’s the F6 button on the lower right. If your train won’t move, first check the track diagram on the fascia to make sure power has been applied to the track (silver toggle switch in “up” position). If the locomotive lights are on and it is producing sound but still won’t move, check F6 to make sure your brakes have been released–you’ll need to do this every time after applying the brakes. Note, one locomotive (L&N C420 1317) DOESN’T have the braking feature, so be careful!

Once the conductor gives you the go ahead, you’ll move the train as needed, holding to the speed limits in the ETT (back of the clipboard) and staying within the authorization of the orders. You’ll need to watch for grade crossings which are marked by whistle posts on the fascia and give the “two long, one short, one long” on the horn (F2 for long and F3 for short on most locomotives along with F1 for the bell). You’ll also act as the fireman / head-end brakeman, handling switching movements and couplings/un-couplings on the front end of the train and protecting grade crossings for forward movements across roads.

You’re welcome to use your own Digitrax or WiFi throttle–the WiFi ID is the only one with “Trains” in the name. If using a layout throttle (usually a Digitrax UT4D) , they work via Digitrax duplex radio. Please KEEP THESE THROTTLES PLUGGED INTO A DIGITRAX JACK WHEN NOT IN USE… 9V batteries are not cheap! The controls are simple. The dials control the address, the “SEL” button acquires the address, the top switch controls direction, and the knob controls your speed. If the locomotive is not responding to the throttle or the “ST” light is red, slide the battery cover off the UT4D, momentarily disconnect and reconnect the battery, replace the battery cover, and press the “SEL” button. The “ST” light should now be green. If it is still red, plug it into a throttle jack on the fascia and press “SEL.” The light should now be green and you can disconnect. If the throttle will still not connect, set the knobs to “0000,” plug it in, and find a new throttle.

You’re encouraged to use the main sound and lighting features of the locomotive. The most important functions are set up for a single button press on the provided Digitrax UT4D throttles.

Headlights (once turned on – “F0”) are directional. Lighting effects – generally headlight dimming or a gyralight for units so equipped – are controlled with F5. The bell and horn are sounded using F1 and F2 (F3 for short horn). If descending a long grade, F4 will turn on the dynamics–this will create the sound of dynamic brakes (for locos so equipped) but won’t affect the speed. Locomotive prime mover “notching” (RPMs) is handled by the decoder for most Locomotives (SoundTraxx DDE). Because of the momentum and automatic notching, it’s useful to “throttle up” quickly using the knob and then dial back to a good running speed (about the 9 o’clock position on the throttle). If you’re starting a heavy train, try raising the throttle with the brake on, then when you hear the prime mover running at high RPMs, release the brake to slowly start the train. When stopping, cut the throttle a good ways out from where you want to stop, then use the brake to control coupling speed and stopping distance. Did I mention brake is “F6”? You might want to remember this.

Crews use “fusees” as needed where there are no blinking crossing signals to protect grade crossings. Pushing the button at the grade crossings lights the fusees for 10 fast-clock minutes. A fusee or flagman isn’t required at every crossing, only those where it makes sense for the crew to protect the crossing due to poor visibility, presence of traffic, unpredictable switching movements that might confuse motorists, etc. Enjoy this little bit of railroadiana, but don’t feel like you have to keep the fusees lit every time you cross or you’ll be fired… just be forewarned you may be asked to submit to substance testing if you do have an incident with an automobile at a grade crossing…

Beyond your paperwork and throttle, everything you need to operate your train can be found on the fascia. The white lines are a track chart that correspond to the tracks on the layout–the thick line is the main, and the thin lines are sidings or secondary tracks. The name of each town and its two- or three-letter destination designator are prominently displayed on the fascia, and each track has both a number across the track line and a label for any industry set-out points on the track that correspond to a destination in the master switch list. All switches are locally controlled. At the junction of two tracks is a round knob that controls the switch. The convention is to press the knob in to route the train toward the back and pull the knob to route the train toward the aisle. The direction of the track lines at each knob indicates which route is “normal” (straight line) and which route is “diverging” (angled line). When leaving a town, all switches should be set to the “normal” position.

Some tracks have a small silver toggle switch on them. This indicates a track where the power can be cut and is usually associated with staging tracks and other tracks where locomotives are kept. This switch helps keep the sound from “non-player” locomotives silent when not in use, so you’ll need to flip the switch up/on to move your train out of staging and flip it down/off to kill the sound of your locomotives when you’re “tied up” in staging and done with your train.

At a few places, a semaphore repeater on the fascia (staff with a light and a flag) indicates the presence of a signal on the layout. The fascia has a repeater light (green, amber, red) for the semaphore which matches the position of the semaphore on the layout. Green means “clear/proceed,” amber means “slow for orders” and red means “stop.” The semaphores at the St. Charles Depot are controlled by the depot operator (simulated) and indicate the presence or absence of new orders. If amber or red FOR THE DIRECTION YOUR TRAIN IS TRAVELING, you should look for your orders hanging from clips near the depot. Since the depot operator is a simulated position, if your orders are the only set, use the controls in the block adjacent to the semaphore diagram to set the semaphore back to green. Trains working the branches will need to set the dwarf semaphores to “red” while working the branch to keep other trains from encroaching. These controls must be unlocked, set, and locked (the key is under the lock) before proceeding. Don’t forget to set the semaphore back to “green” when you’re clear of the branch. The dwarf semaphores also conveniently control the two main areas of hidden track – between St. Charles and Baker on the lower deck, and between the lower and upper decks. If you’re confused about where your hidden train will emerge, you can locate the corresponding letters inside a square on the fascia that indicate the connected ends of hidden track.

Gravity is an important part of mountain railroading, and handbrakes on individual cars are used to hold them on hills when they’re set out. As model cars don’t have handbrakes, there are “handbrakes” in strategic locations around the layout where cars need to be left temporarily without a locomotive to hold them in place. These “handbrakes” are a piece of steel wire between the rails to hold the axles of a car. They’re controlled by a lever on the fascia that engages (angled position) and disengages (straight position) the brake. Running over a brake with a locomotive is not good, so an amber light is a secondary indicator for crews that the brake is extended/engaged. A line of yellow paint on the rail marks the spot where the brake extends–try to get it in front of an axle rather than catching a piece of the car’s body. These brakes will hold 20 cars each without a problem. Of note, there are other more basic “brakes” between the rails (brushes) to help hold (or slow down) cars in a few usual set-out spots.

There are no uncoupling magnets (or coupler trip pins for that matter) on the layout. Crews will need to grab a bamboo skewer to help with coupling/uncoupling. To uncouple, insert the tip of the skewer between the couplers and twist clockwise–it takes some getting used to, but it works. Also, because many couplings occur on curves, you may need to use the skewer to help guide the couplers together. When working under a tipple, it’s often useful to “delay” the couplers (set them so they push on each other but don’t actually couple) when shoving cars into the empty tracks.

Please don’t set things on the layout. The clipboard is your “space” for writing, and there are cubbies for your clipboards all around the layout when you want to go “hands free.” Additionally, the throttles all have clips that can be attached to neck lanyards if you want to keep them on you while using two hands for other things.

If you discover a problem, please point it out to me. This can include cars causing problems (derails more than once), switches/track causing problems (derails more than once), locomotives causing problems (stalls more than once), dirty track, controls not working, etc. No one likes problems, and I can’t fix what I don’t know about.

If you’re overwhelmed by all this, don’t worry. Start with the basics and work up from there:

- Basic: obey your train order times/places, set out your trains cars where they need to go, pick up the cars you’re supposed to pick up, keep train speed slow, use the brake when needed

- Intermediate: block cars per instructions, operate semaphores, keep train speed prototypical and try to ease into couplings rather than braking, use the horn (two longs, a short, and a long) when crossing roads

- Advanced: protect all grade crossings as needed (horns and fusees), use horn signals for train movements when switching, place loads up front / empties in back for all train movements, cut strings of cars at grade crossings to allow automobiles to cross, no locomotives or cabooses under tipples, wait between movements to simulate crews walking the train and connecting air hoses

If you’re not having fun, you’re taking this too seriously–relax and enjoy the laid-back pace of railroading on an Appalachian branch line!

This is the place to check when you’re stumped and need a little help from the old heads who’ve worked these tracks for many years…

Switch list

- Remember the list is sorted first alphabetically by reporting marks (e.g., CG, INT, SOU) then by car number–it’s easier to find cars on the list by looking at the first digits than the last digits.

- Don’t focus on the switch list–focus on the cars in front of you and use the master switch list to inform what you do with those cars.

- There’s not much mystery to the operations–look through the destination of every car in the area you’re working and find the ones coming with you to either set-out or pick-up.

St Charles

- Remember you’ve got a wye! It’s often easier to run around the wye and back a train into the yard. The wye can also serve as a run-around if all other tracks are full.

- For train 61/60, it usually works better to first clear the yard tracks by building your outbound train on the main, then placing the inbounds in the yard tracks.

- When working at the west end of the long yard tracks, you’re on a pretty substantial grade–remember you’ve got a handbrake to hold strings of cars shoved up above the yard tracks.

- If you’re working either of the small tipples, they’re trailing point, so they’ll be a lot easier to work heading out of town, and you can set the loads aside and pick them up on the way back.

Mayflower

- Your run-around is only so long, so be patient and only work one cut of cars at a time. Don’t worry about leaving the rest of the train down near Baker until you finish working the first cut–you own this piece of the railroad!

- Use the long load tracks to stack loads for your outbound train while clearing up tracks to set empties. Once you’ve set the empties on a track, you can fill in the load side without gumming up your future set-outs.

Kemmergem

- How do you run around the caboose and work the facing point tipple at Darbyville without a real run-around? Think of the double-ended tipple tracks as a long run-around–any cars you place behind Kemmergem tipple can later be shoved back onto the main (caboose) or shoved into Darbyville. Use the loads as your “handle” to work these tracks from the other end without going under the tipple.

Benedict

- It’s a set of trailing point stub tracks, so setting out the empties is easy. But it’s also the end of the line with a steep grade back to Turners Siding, so how do you turn the train so the engines are in the lead without a run-around? The same way the prototype crews did – gravity! Note the unique wheels on the fascia here for the adjustable brakes–you can release the brakes and coast 2-3 cars down the tracks and onto the tail track where the locomotives can back in and pick them up.

- If things get crowded, pick a couple tracks to store the loads so you can spot empties, then move the loads onto the tracks where you’ve already spotted empties so you can spot the remaining empties on the now clear tracks.

Monarch

- There’s no run-around here, just facing-point stub tracks. You’ll need to shove the empties from Turners Siding to Monarch.