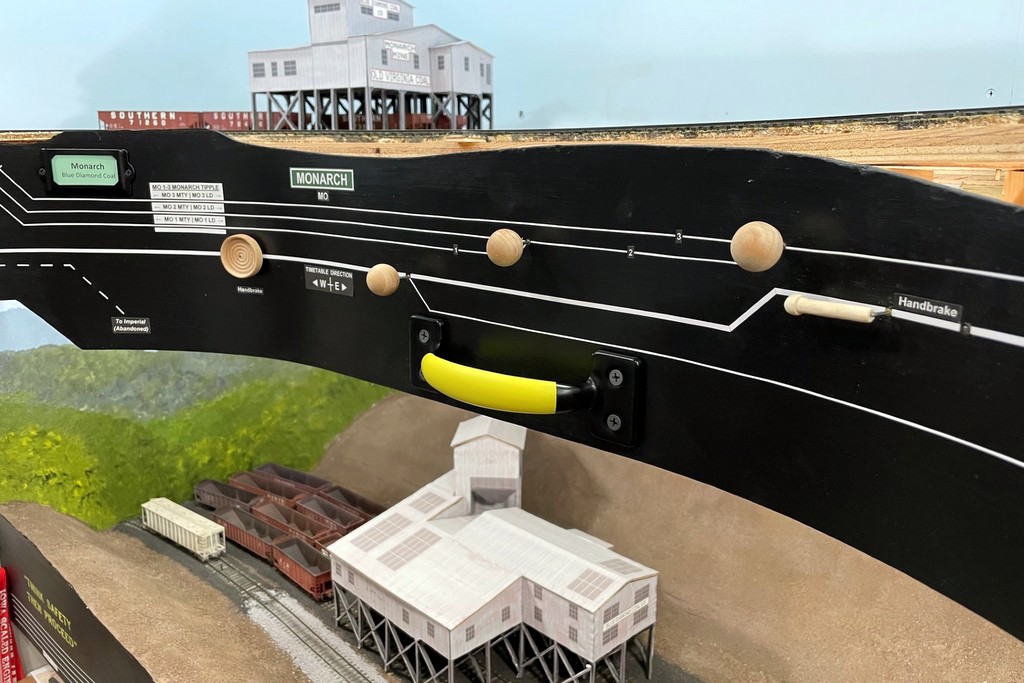

None of us are getting any younger, and at the last operating session, someone mentioned it might be a good idea to install a couple safety handles (grab irons, if you will) above the portable steps where the track height is highest. This made a lot of sense to me, and after running to the local hardware store, I decided on some smooth but strong door handles with four screw holes (most had two). I think vertical handles would have been slightly better, but the benchwork is horizontal, so it made more sense to make the handles horizontal to ensure all four screws would be in solid wood. I also picked up some satin finish yellow spray paint to make the handles more visible–the color is a bit more lemony than I wanted, but the next one was too orange (and I don’t have the patience to trek all over town or the internet looking for the perfect yellow), so I settled. I masked off the ends of the black-finished handles and sprayed the centers.

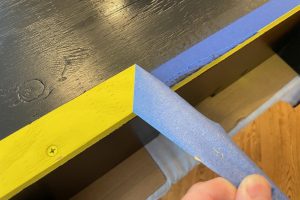

While I was at it, I decided to paint the steps I’d made a while back as well. I wanted to paint the steps with the same black paint as the fascia, but I knew I needed some color to mark the edges and make them easier to see. I sprayed the edges with several layers of the yellow first, then masked off a 1 1/2″ edge and the sides of the plywood top once it had dried. The black was hand-painted, and the resulting step looks much nicer than bare wood, especially with a Southern Railway decal added to the big step to give it a little flair.

To make sure the handles would be good and secure, I glued an extra piece of 3/4″ x 3/4″ wood along the bottom of the 1×3″ benchwork behind the fascia, then I glued 4″x4″ pieces of 1×3″ board behind the benchwork where the screws would go to give them a full 1 1/2″ to bite into, and I used 1 5/8″ screws. The result is a really secure handle! I can imagine one use for these handles being an operator accidentally stepping off one of the steps and grabbing for the handle to keep from falling, so strength was key. I initially installed three handles, one for Benedict, one for Monarch, and one for Kemmergem. The ones at Benedict and Monarch are super solid, but it turns out the benchwork at Kemmergem has just a little too much play to support the weight of a person. The last thing I want is for an operator to fall, grasp the handle, then end up with a chunk of benchwork on top of them, so I removed this one–no biggie as the tracks at Kemmergem are lower and don’t really require a step like the other two do.

While I had the black paint out, I decided it was also time to remove some of the venerable UT4 throttle pockets along the fascia that I reclaimed from my previous layout. These things have served me well for more than 15 years, but with the introduction of the ISE Proto Throttles, the UT4s became redundant. I will still keep two around as backups, but I didn’t need the large banks of throttle pockets taking up prime real estate on the fascia. I installed the pockets before painting the fascia, so I had a little bit of work patching and sanding, but it cleaned up nice.