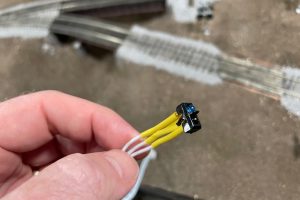

When I installed my automatic detection circuit for crossing signals using infrared (IR) sensors from the WeHonest company, I installed them between the ties. They were initially a bit too sensitive, but after a while of running and changing out lighting to LEDs, the sensors weren’t quite sensitive enough. They would often miss a passing train which is annoying and not up to my standard for how I want things to run on the layout. After reading up online about how this type of sensor works, I tried a super simple and cheap solution that now has them detecting every time!

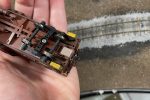

The WeHonest IR sensors are a single unit. unlike paired sensors that detect a break in the IR beam, the single units use a paired IR LED (bluish dome) and IR detector (black dome) and rely on reflected IR energy to close the circuit. Since the bottoms of most of my locomotives and freight cars are flat black, I wondered if they weren’t reflecting enough energy to trip the sensor. To improve the reflection, I stuck a piece of double-sided Scotch tape to a piece of aluminum foil and cut small reflector squares to attach to the bottom of locos and cabooses. I attached them under the coupler, behind the coupler, and even on the bottom of the truck–wherever I could get some good adhesion along the centerline (where my sensors are mounted). It doesn’t have to be perfectly flat because the IR transmitter and detector seem to have reasonably wide beams, so they’ll work with IR reflected at an angle. With just this tiny and simple modification which is invisible from trackside, the IR sensors now work every time without fail!

One concern I have is a piece of conductive material coming loose on the tracks. To mitigate the chance of a short, I cut the rectangles small enough that they can’t bridge the rails in case they accidentally detach in a spot of hidden trackage. They could cause a short if they come loose on a switch, but all my switches are easily reached, so the reflectors would be easy to spot and clear. Thought I’d pass this trick along in case anyone else is struggling with the same issue.

***UPDATE***

This technique worked so well I added tiny rectangles of aluminum to the underside of every car on the layout. It’s easy to find a spot on a coupler pocket or on the center sill that can’t be seen while it’s running. Now there’s almost zero drop out for the signals while a train is crossing.