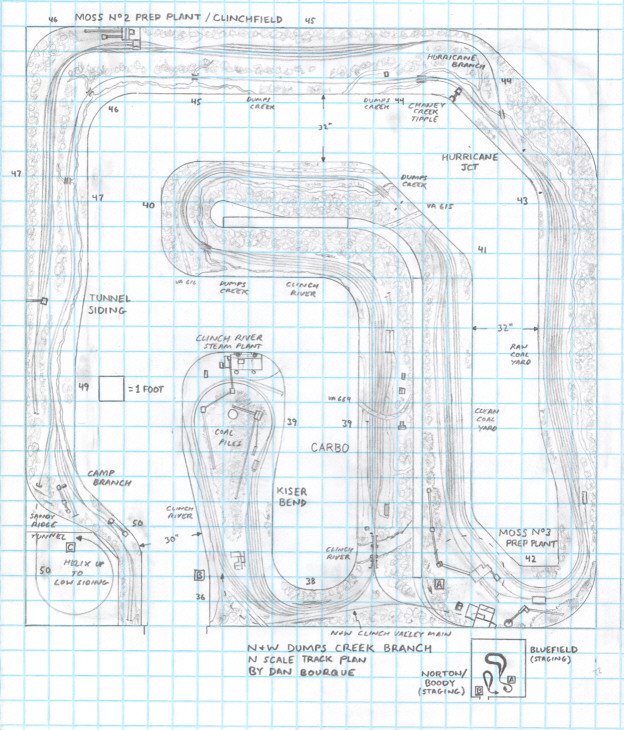

- Size: 23′ x 24′

- Scale: N

- Minimum Radius: 18″

- Minimum Aisle Width: 30″

- Designed by Dan Bourque

The N&W’s Dumps Creek Branch operated more like a self contained short line than a branch. In it’s 16 miles, the signaled branch served several large loaders of the Clinchfield Coal Company, a pair of the company’s large preparation plants and a power plant. It had its own yard at Carbo, VA with a small shop, and it operated big power on several trains daily hauling coal up and over the Sandy Ridge through a tunnel more than a mile long.

The N&W’s Dumps Creek Branch operated more like a self contained short line than a branch. In it’s 16 miles, the signaled branch served several large loaders of the Clinchfield Coal Company, a pair of the company’s large preparation plants and a power plant. It had its own yard at Carbo, VA with a small shop, and it operated big power on several trains daily hauling coal up and over the Sandy Ridge through a tunnel more than a mile long.

The Layout

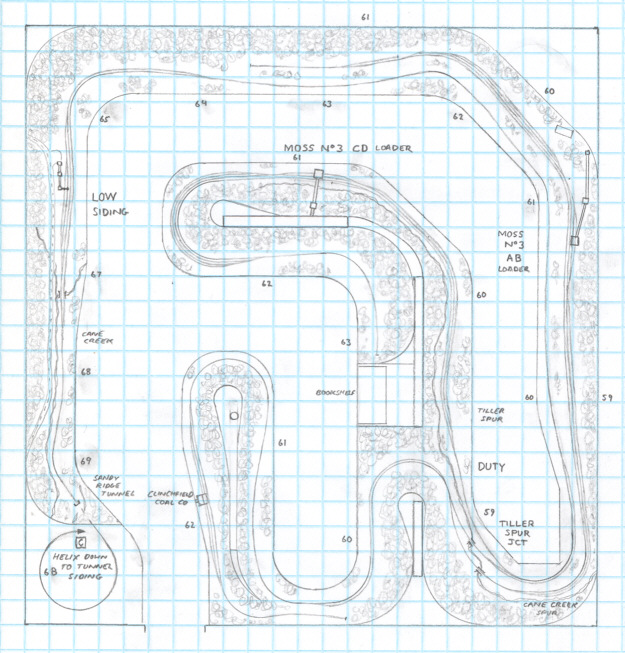

This layout represents the Dumps Creek Branch in its heyday in the 1980s. Even though it’s N-scale, a space the size of a two-car garage is needed to fit everything in, mostly because the tracks for the loaders and prep plants are so long. It includes the Moss No 2 and Moss No 3 prep plants and the large Moss No 3 A-B and nearby C-D loader on the Tiller Spur. Also included are a smattering of smaller truck dumps, some of which are assumptions based on track arrangements rather than photos or other evidence, but they add more variety to the layout. At the end of the line is the Clinch River Steam Plant and the small Carbo Yard and wye adjacent to the N&W’s Clinch Valley Mainline. It’s a two-deck layout with the Sandy Ridge Tunnel encompassing the helix. Track arrangements are very close to the prototype based on 1984 track charts. The layout is relatively uncompressed, and the steep grades on both sides of the tunnel are prototypical.

The staging level is not drawn, but the west-end staging representing the Clinchfield RR connection at Boody, VA and the end of the N&W’s mainline at Norton, VA would be comprised of a handful of tracks in a balloon under the steam plant. East-end staging representing Bluefield, WV would be reached via a short helix under Moss No 3, and a large balloon track with 10 or so tracks would fit under the Carbo peninsula. While there are no duck-unders, the Clinchfield Coal Company tracks at the end of the line past Duty on the upper deck would require an operator to walk around the peninsula. Because it’s a large layout and many trains would operate simultaneously, a high-end DCC system with walk-around throttles would be advisable.

Lower Deck

Upper Deck

Operations

This layout could definitely keep a crew of 6-7 busy for a few hours. Operations on the branch were straightforward, but they would take a lot of time. The basic scheme would have mine runs of 3 6-axles and 40 or so empties departing from Carbo with empties for the loaders and bringing the raw coal loads back to the Moss No 3 Prep Plant’s enormous raw coal yard. Mine runs would finish up by lashing up to a cut of clean coal and hauling back to either Carbo or the Clinch River Steam Plant which got its coal from Moss No 3. Because most of the coal was on the north side of Sandy Ridge Tunnel (the upper deck), mine runs had to fight the 2.1% compensated grade with loads to get to the prep plant. This usually necessitated bringing half a train at a time through the tunnel and dropping cuts at Tunnel Siding. At least three mine runs would be needed to work all the loaders.

On the lower deck, an operator would be needed to work Moss No 3 using the Clinchfield Coal Company’s rare SW600 to take cuts of hoppers of raw coal through the rotary dumper and then under the large tipple for loading with clean coal. Of course, actually dumping and loading the cars would be a bit much, but shuffling them to the right tracks to represent raw and clean coal would add a lot of operation. A yard crew would also be needed at Carbo to make up mine runs and east- or westbound mainline coal trains and to shuttle additional cuts of cars between the yard and Moss No 3 or the steam plant. Another operator could be kept busy bringing mainline trains onto and off of the branch.

For variety or a larger set of operators, the large A-B and C-D loaders along with Moss No 2 could be served twice a day if someone placed loads in the cars and moved them by “gravity” (also known as “fingers”) to the load tracks during a break. The neat thing about the operations is that operators would get to see the whole “circle of life” from empties to raw coal to clean coal to steam plant to empties again in a single session giving the layout a clear purpose.

Things I Like About this Plan:

- Contains an entire major branch line

- Long trains and 6-axle power on a branch

- Captures the entire “circle of life” of coal on the layout

- No duck-unders

- Prototypical track arrangements and grades

- Relatively uncompressed

Things I Don’t Like About this Plan:

- Lots of layout but only coal, coal, coal

- Long helix

- Narrow scope of time (only accurate for the ’80s and ’90s)

Related Products:

Excellent plan Dan, and a great concept for a layout. I was wondering how long it would take before you came up with a trackplan for the Dumps Creek Branch after getting the N&W Clinch Valley book.

Wow, terrific layout. Really love the whole idea. Coal in, coal cleaned, clean coal out, coal to steam-plant, empties returned. After all, that is what Appalachian coal railroading is all about. Thanks again Dan.

Hey Vince, are you still modelling these days?

Dan, do you know any other history about the branch when it was in CRR ownership?

This is a great plan!

I’m afraid I don’t. Didn’t know it was previously CRR.

What is the height distance between levels and staging?

Tom, staging is reached via a helix, so it could be at any level. based on the lower deck height of ~39″, I’d recommend 30″ or so–low enough for visibility but not too low for easy access.