-

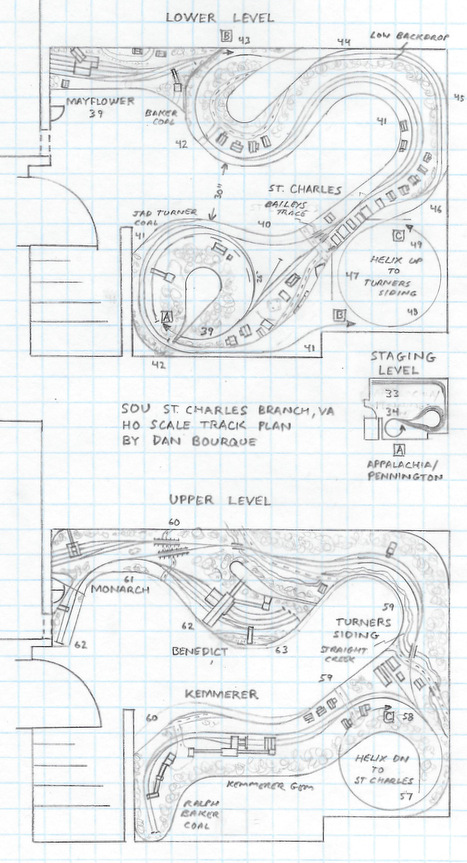

- Size: 12′ x 16′

- Scale: HO

- Minimum Radius: 24″

- Minimum Aisle Width: 30″

- Designed by Dan Bourque

The St. Charles Branch was the Southern Railway’s primary coal branch in Virginia until the acquisition of the Interstate Railroad in 1960. The St. Charles Branch ran from the Southern’s yard at Appalachia, VA for several miles until joining with the L&N at Pocket, VA and heading up Straight Creek to the small yard and wye at St. Charles and several tipples that lined branches north of town. Like many of the Southern’s coal branches in the corner of VA/TN/KY, the line was shared with the L&N who had trackage rights over the St. Charles end of the branch.

The St. Charles Branch was the Southern Railway’s primary coal branch in Virginia until the acquisition of the Interstate Railroad in 1960. The St. Charles Branch ran from the Southern’s yard at Appalachia, VA for several miles until joining with the L&N at Pocket, VA and heading up Straight Creek to the small yard and wye at St. Charles and several tipples that lined branches north of town. Like many of the Southern’s coal branches in the corner of VA/TN/KY, the line was shared with the L&N who had trackage rights over the St. Charles end of the branch.

The Layout

This double-decked layout is designed to fill an odd-shaped unfinished area in a basement (it happens to be my basement), but its dimensions are similar to a bedroom. It represents the end of the branch from St. Charles north including several good-sized tipples. The tipples are a conglomeration of the era between about 1960-1980–they weren’t all active (or standing) at the same time, but including all of them allows for more operations options. For example, the tipple at Monarch and the industry at Turners Siding were gone sometime in the late ’50s or early ’60s, and the small tipples JAD Turner, Ralph Baker and Turners Siding were built sometime in the ’70s.

The lower deck represents the St. Charles area with its wye, depot and tiny yard along with the end of the branch up Bailey’s Trace to the large tipple at Mayflower. The smaller loader for Baker Coal was on the line between St. Charles and Mayflower, but I’ve moved it close to Mayflower for extra operation. The upper deck is reached by a 4-turn helix and represents two branches, the longer branch up Straight Creek to Monarch, VA, and the shorter branch to Kemmerer. The trackwork at the end of the branch to Monarch was complicated with short spurs leading to the tipple at Monarch and the stub-ended, trailing-point branch to Benedict. A staging level sits underneath St. Charles with 3 tracks on a reversing loop and 4 stub tracks along the wall–this is plenty of staging for the few trains that ventured up this line and allows for consists from multiple eras to be staged.

Curves are tight (24″) throughout to accommodate the small room, but the prototypical use of 4-axle power mitigates the operational risk of the tight radius. The layout is designed to be built primarily as open-box benchwork and “hung” from the walls with legs and supports under the turnbacks. Because multiple mine runs plied these rails, a simple DCC system with a booster should be sufficient, and due to the tight aisle, cordless throttles are recommended. I plan on using a Digitrax Zephyr with a booster, UR92 two-way radio receiver, and UT4D radio throttles.

Operations

Operations on this layout can be simple and laid back or jam-packed with switching puzzles depending on which tipples are active and whether or not the L&N is working that day. The branch was home to a Southern mine run, the “Black Mountain Local” in the ’60s and later the “St. Charles Switchers” which used a pair of F-units and later GP38s for mine runs. In the 1960s when times were lean, the L&N served the branch using its CV local three times a week using a single RS3 and a handful of cars from Pennington Gap, VA. The L&N increased its frequency later as coal traffic picked up.

The basic sequence for any operating session is for the Black Mountain Local to start in St. Charles with cuts of empty hoppers delivered the night before. After blocking the cars for the tipples active that day, the local would head up one of the branches working the tipples and bringing loads back home to St. Charles before taking more empties up a different branch. The most time-consuming area to work would be the end of the Monarch line because of the stub arrangement at Benedict. It’s likely crews would take a cut of loads down the steep branch to Turners Siding before returning to complete its work. The short tail track would mean multiple cuts. Crews in the Appalachians often used gravity to help with switching, and Benedict is a perfect candidate. I envision using a retractable brake device under the Benedict tipple to hold strings of hoppers–if the grades are just right, a crew could cut the brakes on a string of cars, ride them up the tail track, then throw the switch to bring them back down the main to the waiting motive power. The Black Mountain Local would finish its work by blocking cars in St. Charles based on destination to decrease the amount of switching needed in Appalachia.

On days where the L&N served the branch, the Southern crew would tie up long enough for the CV Local to work its tipples, only 1-2 judging by pictures, but this could be switched up depending on the day to give the L&N crew more or less work. After the L&N crew left the branch for home rails, the Black Mountain Local would finish up any last-minute switching before the Southern St. Charles Local or an extra would arrive with a fresh set of empty hoppers, pick up the sorted loads, and return to Appalachia.

This layout lends itself to a lot of variety in operations. First, the era determines the tipples that would be active–the later the era, the more tipples. To handle the extra traffic, the Southern ran two mine runs out of St. Charles each day, and the mine runs worked several small tipples between St. Charles and Appalachia–these extra loads could be brought in from staging to make sorting the small yard more interesting. Additionally, more L&N crews could be called to work during busier times, and the tipples shipping on the L&N could be changed from session to session for variety. Finally, motive power changed drastically between the ’60s and ’70s with Southern F-units and L&N RS3s dominating the 1960s and Southern GP38s and L&N C420s in the 1970s.

Things I Like About this Plan:

- Lots of loaders

- Lots of switching

- Two railroads

- Tiny yard and local power

Things I Don’t Like About this Plan:

- Tight curves

- Not much aisle space

- Significant compression in some areas

Related Products:

Nice looking plan and work for the crews thought out decently.

I’m freelancing a version of the NW/SOU merger in West Virginia

While not prototype as being freelance I will be using a lot of proto pics-for ideas.

And your plan helps a lot with some of the head scratching I was doing.

Sorry if this doesn’t fit here feel free to remove it if need be.

Dan

Nice looking plan. Is this the one you will build? If so when will construction begin?

Bill Michael

This is the leading contender, Bill, but I’ve got a while to think about it. I plan on starting in about a year. I’ll let this one marinate for a while, work on benchwork plans, DCC wiring diagrams, staging plans, operations schemes, etc. and continue to refine the plan with research before I’m ready to build.

Dan, I really enjoy all of your St. Charles area plans. Lots of loaders and variety in a small area. I especially like the truck dumps at Pocket, which is what originally attracted my attention to this area. Too bad you can’t squeeze them in somehow. Pocket could make a cool switching puzzle or shelf layout with the loaders, L& N tunnel and bridge, junction, etc. I am still trying to find out it it was worked by the St. Charles local from Andover or the St. Charles mine run from there. Ed Wolfe’s book is great but does not deal in detail abob jobs. Thanks for inspiration. Jon

I agree, Jon–I love Pocket! I tried and just couldn’t manage to fit it into this space without losing the loaders at the end of the line. From my research (which isn’t conclusive), it appears the St. Charles Mine Runs worked Pocket out of St. Charles, at least in later days. What I still don’t know is whether or not they hauled the loads back upgrade into St. Charles for pick up or left them on the siding in Pocket for a crew heading back to Andover to grab. I’m leaning toward the former.

Mr. Bourque, Are you planning to construct a model of the RR yard at St. Charles,VA? I grew up playing in the RR yard and on the coal docks.

I am, and I’d love to pick your brain about the area and what you remember if you’re willing. I’ll send you an email.