RJ Corman Operations at Stifflertown, PA

by Henry Statkowski Photos and figures by the author

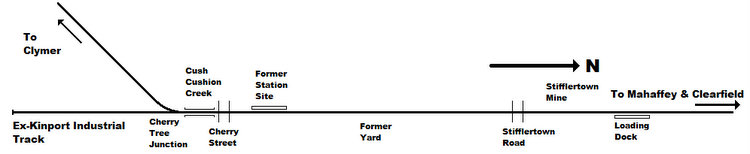

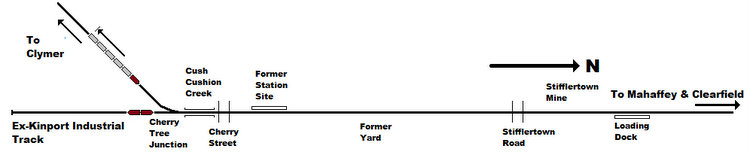

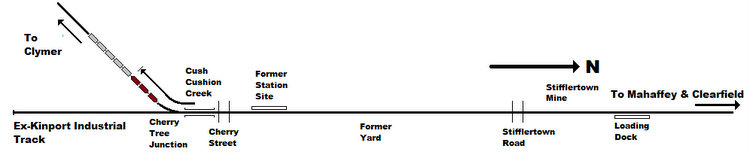

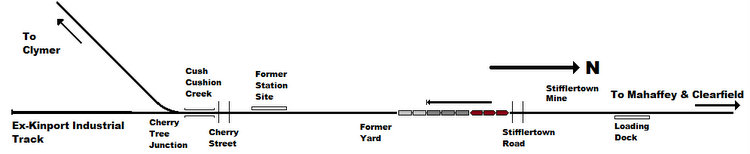

R.J. Corman’s Pennsylvania Line operates a coal train between Rosebud Mining’s Stifflertown, Pennsylvania mine in southwestern Clearfield County and their Bigler coal preparation plant in northeastern Clearfield County. It’s a 60-mile run using SD40-2 variants (SD40-2s & SD40T-2s) and 100-ton coal gondolas, formerly handled by a multitude of coal trucks (locally referred to as “coal buckets”) over public highways. The over-the-road transport was labor intensive – rail transport over already-existing rail lines was a logical step. Loading the train at Stifflertown is performed by front-end loaders at a coal dock, with the coal delivered to the dock by dump trucks from the nearby mine just across the tracks. Unloading the train at Bigler is performed by an R.J. Corman bucket crane – a time-consuming task. Although the coal cars are designed for rotary dumping, no such facilities exist for such at the Bigler site, thus the bucket crane. Coming southward from Clearfield, there are no runaround facilities at Stifflertown, or nearby Cherry Tree. At Cherry Tree Junction the line continues southward on a track which, if reactivated, would continue on to the former Greenwich Mine just past Kinport, but also curves westward at Cherry Tree Junction continuing onward to the Amfire Mining coal preparation plant in Clymer. The following diagram shows the basic track arrangement. The Kinport Industrial Track, continuing straight southward, is only about 150 yards long, the remainder having been removed from the Cambria County portion (possibly for tax purposes), so it’s unable to hold a long string of cars. The line to Clymer, on the other hand, is 13 miles long, but starts immediately with a 14º curve and an 0.8% uphill climb. It’s not the ideal place to shove a string of empty cars, but it doesn’t require any additional construction, either.

R.J. Corman’s Pennsylvania Line operates a coal train between Rosebud Mining’s Stifflertown, Pennsylvania mine in southwestern Clearfield County and their Bigler coal preparation plant in northeastern Clearfield County. It’s a 60-mile run using SD40-2 variants (SD40-2s & SD40T-2s) and 100-ton coal gondolas, formerly handled by a multitude of coal trucks (locally referred to as “coal buckets”) over public highways. The over-the-road transport was labor intensive – rail transport over already-existing rail lines was a logical step. Loading the train at Stifflertown is performed by front-end loaders at a coal dock, with the coal delivered to the dock by dump trucks from the nearby mine just across the tracks. Unloading the train at Bigler is performed by an R.J. Corman bucket crane – a time-consuming task. Although the coal cars are designed for rotary dumping, no such facilities exist for such at the Bigler site, thus the bucket crane. Coming southward from Clearfield, there are no runaround facilities at Stifflertown, or nearby Cherry Tree. At Cherry Tree Junction the line continues southward on a track which, if reactivated, would continue on to the former Greenwich Mine just past Kinport, but also curves westward at Cherry Tree Junction continuing onward to the Amfire Mining coal preparation plant in Clymer. The following diagram shows the basic track arrangement. The Kinport Industrial Track, continuing straight southward, is only about 150 yards long, the remainder having been removed from the Cambria County portion (possibly for tax purposes), so it’s unable to hold a long string of cars. The line to Clymer, on the other hand, is 13 miles long, but starts immediately with a 14º curve and an 0.8% uphill climb. It’s not the ideal place to shove a string of empty cars, but it doesn’t require any additional construction, either.  The train arrives from Clearfield with two or three SD40-2s pulling about 50 cars, with another SD40-2 bringing up the rear. The train continues past the loading site and stops just short of the grade crossing in the center of Cherry Tree, some two-thirds of a mile beyond the loading site.

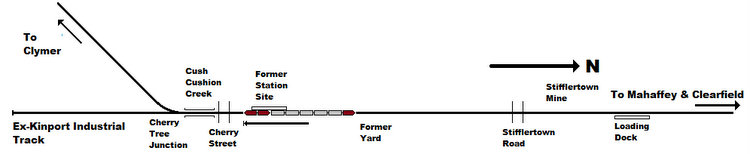

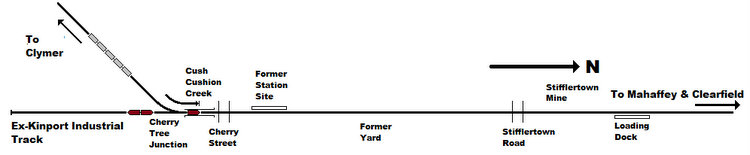

The train arrives from Clearfield with two or three SD40-2s pulling about 50 cars, with another SD40-2 bringing up the rear. The train continues past the loading site and stops just short of the grade crossing in the center of Cherry Tree, some two-thirds of a mile beyond the loading site.  Once stopped, a flagman protects the grade crossing (no flashing lights or gates, yet) and the front engines uncouple and move over the grade crossing, cross the Cush Cushion Creek bridge, and stop on the former Kinport Industrial Track once clear of the switch.

Once stopped, a flagman protects the grade crossing (no flashing lights or gates, yet) and the front engines uncouple and move over the grade crossing, cross the Cush Cushion Creek bridge, and stop on the former Kinport Industrial Track once clear of the switch.  Once the lead engines are clear of the switch, the rear engine shoves the empty coal cars up onto the Clymer trackage until they, too, clear the switch.

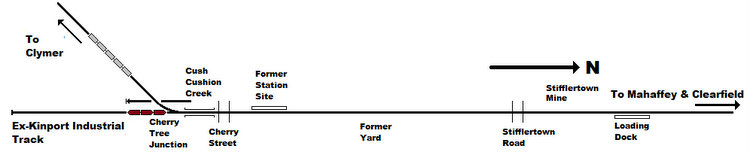

Once the lead engines are clear of the switch, the rear engine shoves the empty coal cars up onto the Clymer trackage until they, too, clear the switch.  After the brakes are set on the string of cars, the rear engine uncouples and comes back onto the bridge.

After the brakes are set on the string of cars, the rear engine uncouples and comes back onto the bridge.  Now it’s time for the rear engine to hook up with the other engines.

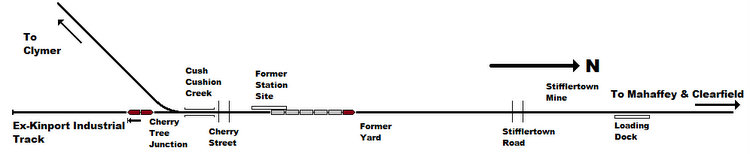

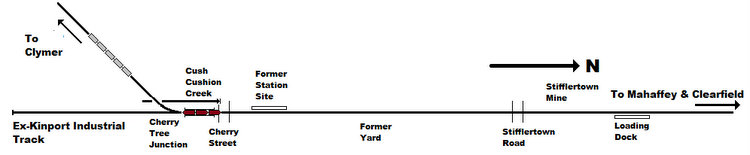

Now it’s time for the rear engine to hook up with the other engines.  The new lash-up comes out onto the main,

The new lash-up comes out onto the main,  And backs up to the waiting cars, coupling up and charging up the brake lines.

And backs up to the waiting cars, coupling up and charging up the brake lines.  Once everything is good to go, there’s more blowing of the air horns, more flagging, and the train pulls northward out of Cherry Tree, continuing past the remains of the former New York Central yard, stopping just before the Stifflertown Road grade crossing.

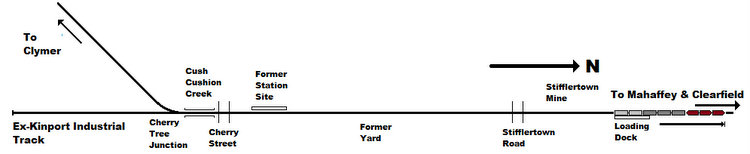

Once everything is good to go, there’s more blowing of the air horns, more flagging, and the train pulls northward out of Cherry Tree, continuing past the remains of the former New York Central yard, stopping just before the Stifflertown Road grade crossing.  Why the Stifflertown Road stop? Well, the grade crossing (this one is equipped with flashing lights and gates) can’t be blocked while the train is being loaded, and the distance between the grade crossing and the loading dock isn’t long enough to hold a 50-car string, with or without engines – fifteen cars have to be temporarily left behind. And why can’t Stifflertown Road get blocked? Because this is how the coal is delivered from the nearby mine on the north side of the tracks to the loading dock on the south side of the tracks, which needs continuous replenishment during the loading operations. So, the train leaves about fifteen cars behind, pulls forward to the loading dock, and the front-end loaders start filling up a string of about ten cars’ worth, the length of the loading dock. The front-end loaders, two on one side of the coal pile and one on the other, take less than three minutes to fill each car with close to 100-tons of coal from the coal pile.

Why the Stifflertown Road stop? Well, the grade crossing (this one is equipped with flashing lights and gates) can’t be blocked while the train is being loaded, and the distance between the grade crossing and the loading dock isn’t long enough to hold a 50-car string, with or without engines – fifteen cars have to be temporarily left behind. And why can’t Stifflertown Road get blocked? Because this is how the coal is delivered from the nearby mine on the north side of the tracks to the loading dock on the south side of the tracks, which needs continuous replenishment during the loading operations. So, the train leaves about fifteen cars behind, pulls forward to the loading dock, and the front-end loaders start filling up a string of about ten cars’ worth, the length of the loading dock. The front-end loaders, two on one side of the coal pile and one on the other, take less than three minutes to fill each car with close to 100-tons of coal from the coal pile.  Ten cars filled? Pull forward for the next ten. Once twenty cars, or so, are filled, the loading crews take a break and the train backs up to retrieve the remaining cars.

Ten cars filled? Pull forward for the next ten. Once twenty cars, or so, are filled, the loading crews take a break and the train backs up to retrieve the remaining cars.  Everything gets coupled together, and its back to the loading platform for the rest of the day’s coal.

Everything gets coupled together, and its back to the loading platform for the rest of the day’s coal.

The remaining empty cars are now loaded, ten at a time and, once the train is fully loaded, the End of Train Device added to the last car and the air brakes charged and tested, the train finally heads northward towards Bigler. The train travels over former NYC tracks to Curwensville, former B&O tracks into Clearfield, more former NYC tracks to Bigler, and finally former PRR tracks to access the Rosebud Mining complex. Once upon a time, Clearfield County was a hodge-podge of NYC and PRR tracks, crossing and sometimes even connecting with one another, but that’s another story. No, the Bigler Shuttle, as it’s called, is not as high-tech as some coal train operations, with balloon tracks and flood loaders, but it gets the job done – at minimal cost. For model railroad purposes, here the modeler wouldn’t even have to build the coal mine, just the loading site serviced by dump trucks. Will Rosebud Mining ever install a conveyor system from the mine to the loading dock, as has been done in other locales? Possibly, maybe, maybe not. And, what’s exactly involved with unloading the train at the other end of the line? That’s another story, too.

Related Products: