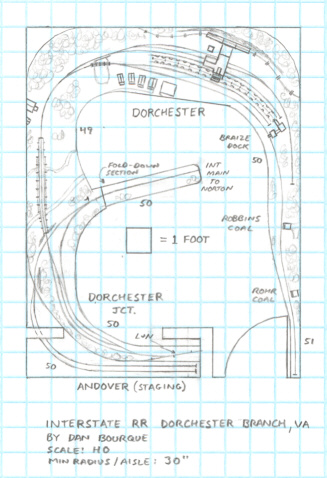

- Size: 11′ x 14′

- Scale: HO

- Minimum Radius: 30″

- Minimum Aisle Width: 30″

- Designed by Dan Bourque

![]() It’s difficult to get a lot of operation into a small bedroom. The most common solution is to build a switching layout to get enough operation since a small slice of mainline or branchline is often too compressed for much operation. The Interstate Railroad’s Dorchester Branch, however, packs a lot of operation into a short branch with some interesting switching challenges making it a great prototype for a bedroom layout.

It’s difficult to get a lot of operation into a small bedroom. The most common solution is to build a switching layout to get enough operation since a small slice of mainline or branchline is often too compressed for much operation. The Interstate Railroad’s Dorchester Branch, however, packs a lot of operation into a short branch with some interesting switching challenges making it a great prototype for a bedroom layout.

From Dorchester Jct., the Dorchester Branch crosses the Interstate main at grade and immediately crosses the long, low Dorchester trestle before arriving at Dorchester where a decent sized tipple and bank of coke ovens resided. Further up the branch were three loaders, one to load crushed coke from Dorchester and two small coal tipples. Three things made working the Dorchester Branch challenging. First, everything on the branch was a stub track–everything had to be shoved up the branch caboose first. Second, there was no direct route from the Interstate main–crews had to bring the train up to the L&N at Dorchester Jct. to be able to shove back up the branch. Finally, three of the loaders loaded directly onto the main–all the loads had to be cleared before the empties could be spotted.

After the Interstate dieselized in the early ’50s, Dorchester tipple’s owner, Wise Coal & Coke Co., bought an ex-Interstate 2-8-0, and later an ex-N&W steamer, to work the tipple. Ed Wolfe describes how the WC&CCo. would work with the Interstate crews to line up their loads in his second book on the Interstate. Even with the help, the Interstate crews would often have to take loads in cuts to get upgrade into Dorchester Jct.

The Layout

The Dorchester Branch layout is designed to be operated just the way the prototype was in the ’40s and ’50s when everything was still active on the branch (I’m not exactly sure when Robbins and Rohr Coal shut down, but they weren’t long lived). It also captures the Interstate trackage at Dorchester Jct. which adds to the switching fun. Scenically, there is enough room to model the trestle, tipple and coke ovens fairly true to prototype.

The narrow center peninsula gives just enough of the Interstate mainline to cut a mine run in two and shove it into the side tracks at Dorchester Jct., and it is designed to fold down to open up the center of the room for other uses. Aisles are generous for a small layout to give 2 operators plenty of space, and at 30″, curves are large enough to look good, especially since they’re mostly viewed from the inside at chest level, and the locomotives and hoppers are short. Staging tracks are about 8 feet long. That equates to about 12 hoppers, an RS3 and a cab–about right for a Dorchester mine run, though more cars could be pre-staged at Dorchester Jct.. This layout could easily be powered by any of the startup DCC systems, but a walk-around throttle is a must.

Operations

This layout would be great for 1-2 operators, and based on my own experience (my layout includes the Dorchester Branch), it would take about 1 hour to work everything. The crew would pick up their Dorchester Mine Run of empty hoppers in Andover (staging) and proceed to Dorchester Jct. Upon arrival, the crew would break the train in two and spend the next several minutes running around cars and piecing the train back together before shoving it up the branch cab first. At Dorchester, the crew would need to set the empties on the main and clear out loads from the tipple and coke tracks before spotting the empties. To make things more challenging, a few “partial loads” of coke could be placed in inconvenient places–the crew would have to pull them, place empties and then replace the partial.

Once Dorchester was worked, the crew would proceed up the main to collect the handful of loads from Braize Dock, Robbins Coal and Rohr Coal. Once the loads were clear, the empties could be spotted starting with Rohr, then Robbins and finally Braize Dock. Finally, the loads could be gathered and run out 6-8 at a time (on account of the grade) to Dorchester Jct. Unfortunately, the short peninsula means the first set of loads would have to be run-around and shoved into staging before gathering the rest. While not exactly a prototypical problem, this would add a few switching moves.

To add variety, loads bound for the L&N, N&W or Clinchfield might have to be switched out and left at Dorchester Jct. for a later Hill Crew (unmodeled) to take care of. Also, if modeling the earley diesel era, the Crew could also operate the WC&CCo. 2-8-0 before the Dorchester Mine Run to line up all the loads and then again after the mine run to set all the empties in the coke yard.

I think this would be a great choice for the modeler with limited space who wants to model the coal fields and do a lot of switching. I sure have enjoyed running a similar Dorchester Mine Run on my own layout, so this is one I can vouch for!

Things I Like About this Plan:

- Switch for switch with the prototype

- Relatively uncompressed

- Generous aisles and curve radius for a small layout

- Interesting switching challenges

- Steam and diesel on the same layout

Things I Don’t Like About this Plan:

- Short “tail track” (Interstate main) at Dorchester Jct.

- Short staging tracks

- Staging might be difficult to access

Related Products: