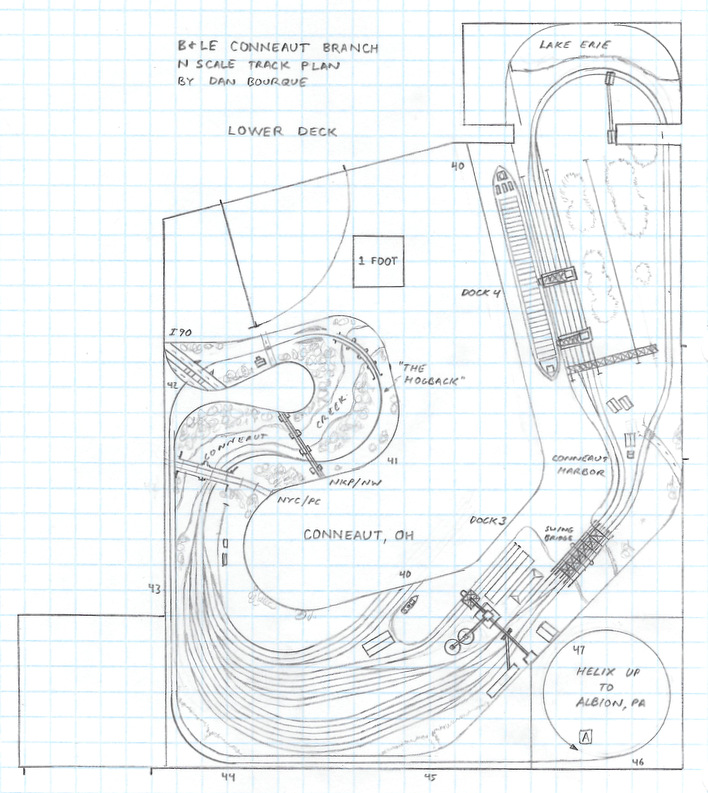

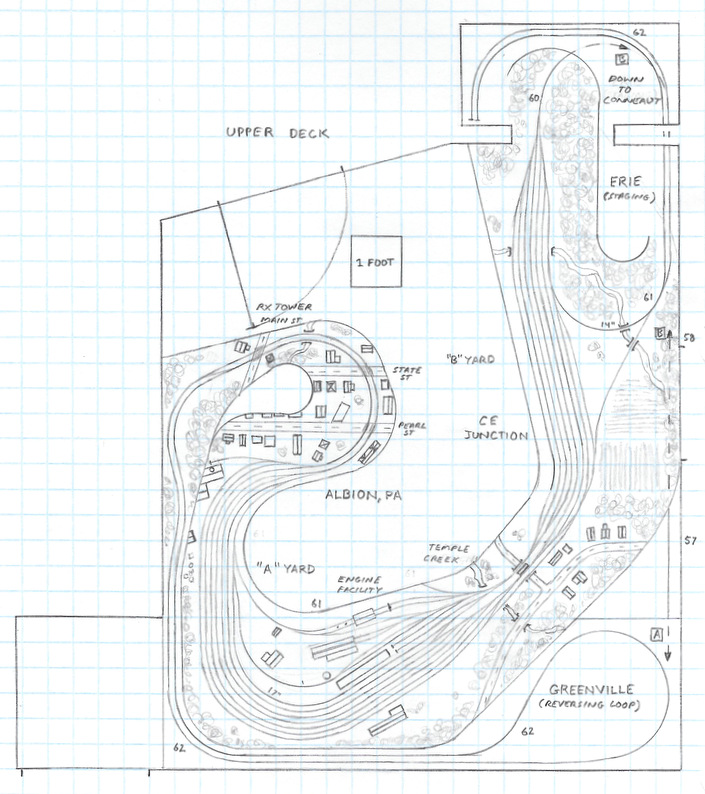

- Size: 10′ x 15′

- Scale: N

- Minimum Radius: 15″ (except as otherwise noted)

- Minimum Aisle Width: 30″

- Designed by Dan Bourque

The Conneaut Branch ran 16 miles from Albion, Pennsylvania to the B&LE’s Great Lakes port of Conneaut, just across the Ohio border on Lake Erie. While it was originally listed as a branch, several trains per day including the majority of the B&LE’s coal and iron ore traffic ran over this line which included some neat scenic, mechanical and operational features including multiple docks and huge “Hulett” unloaders, a 4-track swing bridge, a stone arch overpass, the “hogback,” helpers, and a major yard complete with engine facilities.

The Conneaut Branch ran 16 miles from Albion, Pennsylvania to the B&LE’s Great Lakes port of Conneaut, just across the Ohio border on Lake Erie. While it was originally listed as a branch, several trains per day including the majority of the B&LE’s coal and iron ore traffic ran over this line which included some neat scenic, mechanical and operational features including multiple docks and huge “Hulett” unloaders, a 4-track swing bridge, a stone arch overpass, the “hogback,” helpers, and a major yard complete with engine facilities.

The Layout

This track plan represents the Conneaut Branch in the 1970s. Dont’ let the “branch” name fool you, the Conneaut Branch is home to some BIG railroading. The challenge with this track plan was capturing some very large facilities and yards in a bedroom without a ridiculous amount of compression. To get there, I chose the key features and areas that would allow realistic and “big” operations. The “must haves” are the port of Conneaut, OH, the yard at Conneaut, and the yard and facilities at Albion, PA.

The port of Conneaut is the lowest point on the B&LE, so I chose to make this the lower deck. I included a small version of the yard, but there was no way to model the entire port facility. Instead, I chose to model Docks 3 and 4 where coal was loaded into ships and ore was unloaded, respectively. I also included the one-of-a-kind, 4-track swing bridge (to scale) that would be a scratchbuilder’s delight and conversation piece. The Dock 4 facility includes the small yard under the enormous “Hulett unloaders” (there were 4 but I’ve only drawn 2) next to an ore ship (more modeling fun). The reversing loop is prototypical, and the mounds in the middle of the loop were for open storage of ore. Dock 2 was home to the tugs. Dock 1 was used for limestone, and this traffic can be modeled using the small stub yard that runs off into the aisle. The remainder of the lower deck is dedicated to a couple of railroad overpasses (including a double stone arch on the NYC overpass) and the “hogback,” a question-mark shaped loop that allowed trains to ascend inland on a 1% grade that still required helpers on heavy ore trains.

The second level, reached via a helix, represents the large yard at Albion, PA. From here, northbound trains left the B&LE main to travel to either Conneaut, OH or Erie, PA via trackage rights on the Nickel Plate/N&W. Albion was originally comprised of several yards, but in this era, it had been consolidated into the “A Yard” and “B Yard.” You’ll notice this plan doesn’t have a staging yard–the “A Yard” is used as visible staging while the “B Yard” is used for classification and assembly. The yard also includes the small engine terminal and car shops in addition to the wye connecting to the Erie Branch. The B&LE mainline to the south is a simple reversing loop that allows trains to be run beyond scenery and returned to the yard. This loop also allows for a form of continuous running by having reversing loops at both ends of the layout.

Construction of this layout would be straightforward with the most difficult engineering (and greatest amount of hidden track) being the helix. A small nook in the bedroom used for attic access also gives a handy access point to some of the hidden tracks. An advanced DCC system would be very beneficial to this layout, especially for adding and removing helpers and running helpers up and down the helix.

Operations

This layout could easily employ 4-5 operators, but there’s probably only room for about 3. Albion and Conneaut would both warrant a yardmaster leaving the third operator as a road crew to shuttle trains back-and-forth between Albion and Conneaut. An operating session would start with everything visibly staged. Conneaut would be full of hoppers loaded half full with iron ore (it’s a lot heavier than coal) under the Hulett loaders at Dock 4 and in the yard closest to the wall, empty hoppers in the middle yard, and some empty covered hoppers in the yard cutting into the aisle representing Dock 1 limestone traffic. Albion would be full of hoppers loaded with coal and some covered hoppers full of limestone. The B&LE used the same hoppers to haul both coal and ore making for more efficient and revenue-producing movements of hoppers. A pair of trains full of mixed freight would be staged in the Erie, PA staging tracks.

The basic cycle on the layout is 1) getting hoppers of coal from Albion to Conneaut Dock 3, 2) getting empty hoppers from Dock 3 to Dock 4, and 3) getting hoppers of ore from Dock 4 to Albion. The Albion yardmaster would pull strings of cars from the A Yard and classify them in B Yard. When a train is ready to head to Conneaut, the road crew is called to grab two sets of engines (front end and helpers) and a cab to add to the train and head off to Conneaut–on the way downgrade from Albion to Conneaut, the helpers were used for distributed braking. Meanwhile, in Conneaut, the yardmaster, using 1 or 2 F-7s for switching, would be busy pulling loads of ore from Dock 4 into the yard and replacing them with empties from Dock 3. Once the road crew arrives in Conneaut, it drops its loads of coal in the yard and trades them for a string of ore hoppers. Replacing the helpers, it departs via the “hogback” for Albion. The Conneaut Yardmaster would have to switch the new loads of coal into Dock 3 while at Albion, the newly arrived road crew would drop its loads of ore in Yard A or Yard B and return its locomotives to the engine facilities.

Of course, there was more traffic in this area than just coal and ore. The covered hoppers for limestone would need to be shuttled from Dock 1 tracks to Albion as well and vice-versa. Finally, the trains from the Erie Branch would be run into Albion, adding a variety of interchange and industrial traffic to the mix and giving the Albion Yardmaster more classification to do. Likewise, some of the strings of cars visibly staged in Yard A at the beginning of the session would have Erie-bound cars to be classified into trains to return to Erie later in the session. All-in-all, operations on this layout would move a lot of cars!

Variety in the traffic could be gained in many ways. First, the ore and coal traffic across the Great Lakes was seasonal, so on the shoulders of the season, there might be times where only coal or only ore is moving. These commodities were also heavily affected by the market values of coal, iron ore and steel, so some months would see much heavier traffic than others. Also, the tracks didn’t change much from the 1950s through the 1980s, so different motive power could be run. In the ’50s and early ’60s, the line would be dominated by F units with some 6-axle Baldwins (DRS-6-6-15s and AS-616s) and Alcos (RSD-15s). In the ’60s, the 6-axle EMDs were starting to take over, including SD7s, 9s, 18s and 38s. The ’70s saw the retirement of the non-EMD units and added SD38ACs and SD38-2s. The F-units remained as switchers into the ’90s.

Things I Like About this Plan:

- A lot of big railroading in a small space

- Credible representation of a major port

- Scratchbuilder’s dream (Hulett unloaders, swing bridge, docks)

- Ability for continuous running with two reversing loops

- Coal/ore focused but with a decent mix of non-hopper traffic

- No need for offline staging

Things I Don’t Like About this Plan:

- Not much room for operators

- Lots of track and switches for the space

- Many switches would need to be modified to support curves

- Helpers running on hidden track

Related Products:

Great idea and execution. Love lake freighters and the loads both ways concept. Hope someone builds it some day.