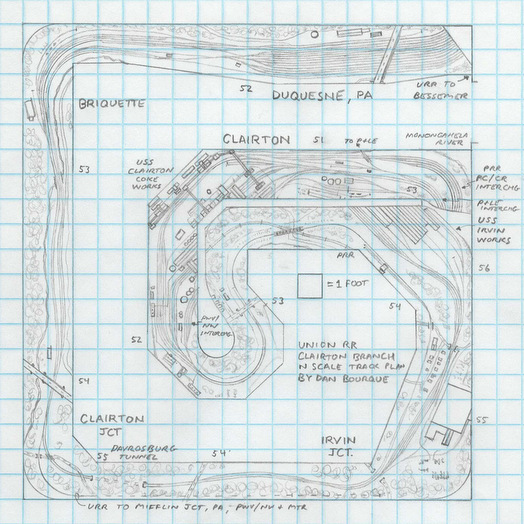

- Size: 18′ x 19′

- Scale: N

- Minimum Radius: 15″

- Minimum Aisle Width: 30″

- Designed by Dan Bourque

This plan is good for those who like big industries and modeling a small area in a big space with little compression. The Union Railroad has served US Steel’s Pittsburgh, PA steel mills for more than a century. While the URR’s own coal tipples played out long ago, the Union still hauls a lot of coal from it’s coal-hauling neighbors and serves the largest coke plant in the nation at Clairton. N scale was chosen for this layout to allow the huge industrial complexes in this area to be modeled near scale size.

This plan is good for those who like big industries and modeling a small area in a big space with little compression. The Union Railroad has served US Steel’s Pittsburgh, PA steel mills for more than a century. While the URR’s own coal tipples played out long ago, the Union still hauls a lot of coal from it’s coal-hauling neighbors and serves the largest coke plant in the nation at Clairton. N scale was chosen for this layout to allow the huge industrial complexes in this area to be modeled near scale size.

The 6-mile long Clairton Branch, following the Monongahela River for much of its route, represented the southernmost portion of the 30-mile Union Railroad and was home to two major sites in US Steel’s Pittsburgh empire, the Clairton Coke Works and the Irvin Works. Clairton took coal received via barges and turned it into high grade coke for all its Pittsburgh furnaces and the furnaces of many other customers in the northeast. Irvin works took brand new steel from the blast furnaces at nearby Duquesne and Edgar Thompson Works and rolled it into coils and other products to be shipped to manufacturers around the nation for further shaping. Duquesne Works shut down in the 1980s, but Clairton and Irvin are still in operation allowing this layout to represent any era from the late steam era to present day.

The Layout

This layout is designed to represent the Clairton Branch in its entirety with minor compression compared to most layouts–the run from Clairton to Clairton Jct. is about two scale miles, around 1/3 of the actual track miles. The key scene of the layout is the US Steel Clairton Coke Works with its numerous yards, barge unloading facilities, banks of ovens and the large tipples on both ends. Irvin Works is also modeled with its key tracks, yards and junction. To save space, both of these industries are modeled with the buildings set at an angle into the backdrop to allow most of the buildings to be suggested without taking up too much space. The layout is intended to be uncompressed and uncomplicated, so there is no attempt to cram more track into the space. Instead, there is ample running distance between scenes to allow the rolling hills along the Monongahela to be modeled. In all cases, the aisle side is the river side, so the hills run prototypically up into the backdrop.

In addition to the Clairton Branch, the URR’s mainline from Clairton Junction to Duquesne is also modeled. Duquesne was a large yard and the center of activity on the south end of the railroad. On the layout, it serves as both a classification yard and a visible staging yard. A receiving yard between Briquette and Duquesne allows trains to push their cars into the yard so the power can be used on another train. Duquesne staging represents the north end of the railroad including connections with corporate partner B&LE and other roads as well as the Edgar Thompson Works, both a receiver of coke from Clairton and a shipper of raw steel to Irvin. While only the Union’s tracks are modeled (except for a small piece of the Pennsy), the URR’s portion of the yards used for interchange around Clairton allow these important interchanges to factor heavily into operations. The connection with the P&LE was reached via bridge across the Monongahela River just south of Clairton, but for purposes of this layout, the interchange traffic is left at the small yard on the Clairton side of the river. Additionally, a small yard on the west side of the Clairton Works has been borrowed to provide the interchange for the P&WV/N&W that occurred a bit farther down that line.

There is very little hidden track on this layout and only one hidden staging track representing Mifflin Jct, an important interchange with the P&WV/N&W and Montour. This staging track could easily be expanded into a small yard if more traffic was desired, but the focus here is the Clairton Branch industries and Duquesne. Because of the number of engines the URR ran in this area, DCC would be a must, and an advanced system and walk-around control would be needed.

Operations

This layout could easily keep 6-10 operators busy for hours, and while N scale isn’t known as the best scale for switching operations, the use of long cuts of cars in the industries modeled mitigates this a bit. I have little actual knowledge of operations in this area, so these descriptions are a best guess based on the known flow of materials in this area. Jobs would include a dispatcher, a yard crew at Duquesne, a US Steel switching crew to accomplish inter-plant switching duties at Clairton and Irvin, and 2-3 road crews. Prior to an ops session, Duquesne would be staged with 1-2 trains of steel slab, 1-2 trains of empty coke gons, 1-2 trains of empty gons or steel coil cars, and a couple of mixed freights with boxcars, tank cars and others to handle the remaining industries and chemical products of Clairton. The three interchange yards at Clairton would be filled with empty hoppers, while the receiving yard and both tipples would be filled with loaded coke hoppers. The Mifflin Jct. staging might perhaps contain a train of loaded Montour hoppers bound for the B&LE’s port at Conneaut, OH.

Trains might work like this. An empty coke hopper train led by 4-5 EMD switchers would leave Duquesne for Clairton to start the process. Once there, the empties would be swapped out for loads in the receiving yard before returning to Duquesne. These trains had to move upgrade from Clairton to Davrosburg Tunnel, and a 15 mph crawl was common. A train might even need to leave some cars at Irvin Jct. to double the hill up to the tunnel. Once at Duquesne, the crew would run around their train at Briquette and shove it into Duquesne, simulating delivery to the Duqesne or Edgar Thompson Works just off the layout. In the meantime, switching crews at Clairton would begin shuttling some of the loads from under the tipples and replacing them with the newly delivered empties and working a few of the other tracks around Clairton moving strings of tank cars and other non-hoppers around.

Irvin would be worked in a similar manner with a train leaving Duquesne with steel slab bound for Irvin, the product of the Clairton Coke delivered in a previous session. These cars would be run around in the small yard at Irvin Jct and shoved up to Irvin where they could be swapped for empties before returning to Duquesne. Later in the day, this process might be repeated only with empty coil cars moving from Duquesne to Irvin and being replaced with loads of steel coils. A plant switcher would also be needed here to shuttle strings of cars around and get them to the proper tracks.

The yard crew at Duquesne would be busy placing power on the next outbound train and classifying inbound trains. It’s envisioned that the back half of the yard would be used for staging and the front half for classification. A local from Duquesne to Clairton might work the smaller industries along the line and take interchange traffic to the yards at Clairton and back. At some point in the session, a train of loaded coal hoppers from Mifflin Jct. would run to Duquesne as well. The next Clairton run might have fewer hoppers in tow, instead pulling the empties from the interchange yards at Clairton and replacing them with loads left in the receiving yard at Clairton and bound for the PRR, P&LE or P&WV/N&W.

There would be many ways to add variety to operations. The first would be by changing the era. URR trains in a 1970s session might include a few “buffaloes,” Baldwin 6-axles remotored with EMD prime movers. A session where the URR was testing out heavier 6-axles would justify a few orange-and-black SD9s or SD38s from the B&LE, some of which might even be in Duluth, Missabe and Iron Range or Elgin, Joliet and Eastern colors. The cars would also change for different eras, especially the hoppers used and the cars used to transport steel coils. Another variation would be to change the interchange patterns with more or less going to the connections at Clairton.

Things I Like About this Plan:

- Big industries modeled fairly well

- Little compression

- Simple design with little hidden trackage

- Generous aisles in most areas

Things I Don’t Like About this Plan:

- Wasted aisle space

- No continuous running

- Stub-ended yard and staging at Duquesne

Related Products: