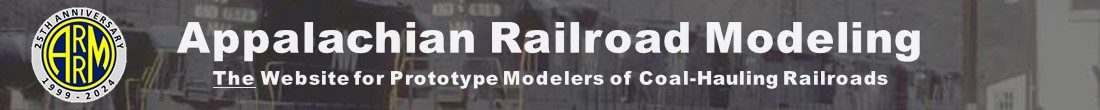

- Size: 27′ x 30′

- Scale: HO

- Minimum Radius: 30″

- Minimum Aisle Width: 30″

- Designed by Dan Bourque

The C&O was the king of coal hauling in the Appalachians, and some of the largest operations it served were in eastern Kentucky on the Big Sandy Subdivision. One of the coolest parts of the Big Sandy was the area geographically south of Martin, KY including the Long Fork Sub and Elkhorn & Beaver Valley (E&BV) which followed the left and right forks of Beaver Creek, respectively. The Long Fork Sub was densely packed with loaders of all shapes and sizes including the huge prep plant at Price, a relic from the steam era that loaded coal into the 1980s. The E&BV was less densely populated with loaders, but it packed some large flood loaders including Stinson, at one time the C&O’s leading loader of coal. The E&BV also crossed over tall trestles to reach the loaders at Deane, KY and a connection with the L&N’s Rockhouse Creek Branch, part of the Eastern Kentucky Sub. For those modeling the 1980s, these two subs offer a variety and concentration of loaders that rival the steam era.

The C&O was the king of coal hauling in the Appalachians, and some of the largest operations it served were in eastern Kentucky on the Big Sandy Subdivision. One of the coolest parts of the Big Sandy was the area geographically south of Martin, KY including the Long Fork Sub and Elkhorn & Beaver Valley (E&BV) which followed the left and right forks of Beaver Creek, respectively. The Long Fork Sub was densely packed with loaders of all shapes and sizes including the huge prep plant at Price, a relic from the steam era that loaded coal into the 1980s. The E&BV was less densely populated with loaders, but it packed some large flood loaders including Stinson, at one time the C&O’s leading loader of coal. The E&BV also crossed over tall trestles to reach the loaders at Deane, KY and a connection with the L&N’s Rockhouse Creek Branch, part of the Eastern Kentucky Sub. For those modeling the 1980s, these two subs offer a variety and concentration of loaders that rival the steam era.

The Layout

This track plan is designed for a large basement and captures the E&BV and Long Fork Subs at they appeared in the last days of the C&O in the early ’80s. This plan captures a LOT of railroad, so despite the large space, it still required two decks and a good bit of selective compression to make it fit. This plan captures a whopping 23 coal loaders including 3 large flood loaders and the huge prep plant at Price. It also captures all the key operational areas including the yard at Martin, KY, numerous branches, and the L&N connection at Deane. It’s a down-up-down design for the E&BV making for hours of running room from end-to-end, and the L&N and C&O staging underneath are connected to form a continuous running loop when you just want to run trains. Despite running two branches, both on two levels, operators don’t have to walk around anything to follow their train between levels while working either sub.

The heart of this area is Martin, KY, home to a modest yard from which the “shifters” were dispatched to the loaders on both the Long Fork and E&BV. The model yard lays out very similarly to the prototype with an L-shape. The E&BV and Long Fork subs split just outside of the yard. Because the E&BV enters a tunnel and the Long Fork loaders start almost immediately, I chose to model the Long Fork on the lower deck while taking the E&BV to the upper deck (skipping a few nice loaders near Eastern, unfortunately). All of the Long Fork loaders save one at the very end of the line are represented here including the short branches at E. McDowell and Salisbury (Spurlock Spur). I did have to modify the track arrangements at some loaders into stub tracks to get everything to fit, but there are run-arounds near all of the stub arrangements. The branch at E. McDowell conveniently wraps around the helix near the entrance. Both the E&BV and Long Fork Sub enter the double-tracked main helix at the same elevation.

Lower Level

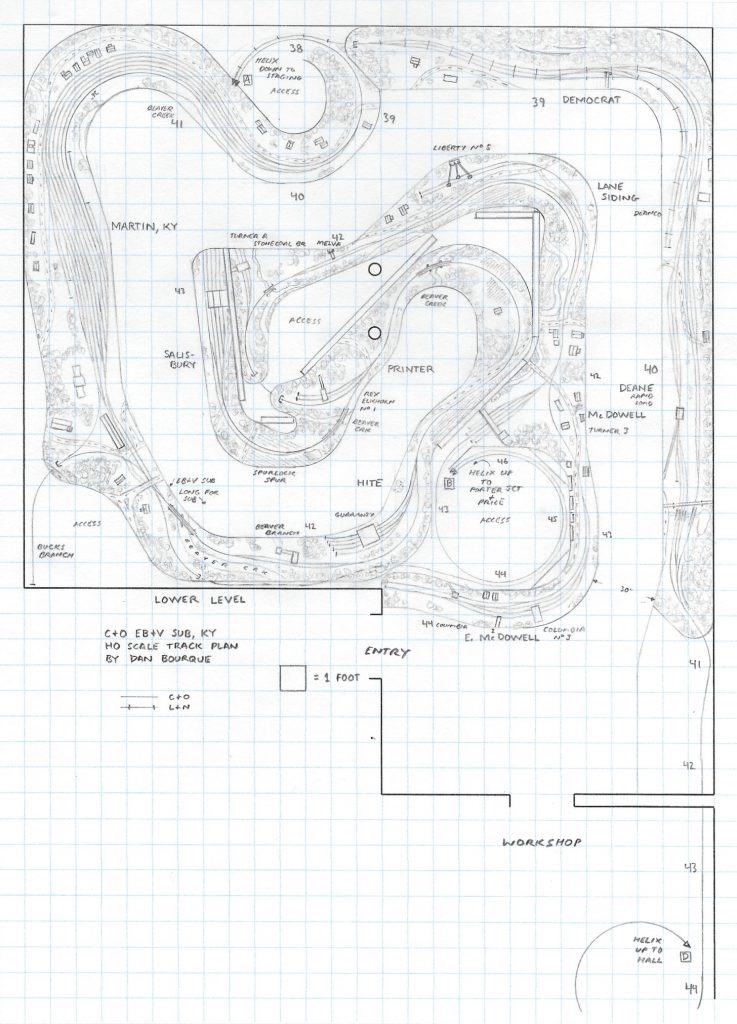

On the upper level, the Long Fork Sub re-emerges from a tunnel (prototypical) near the entrance to the layout and continues to the large (20 linear feet) arrangement at Price, a key scene on the layout. Instead of following the main from Price, the layout follows the shorter Clear Creek Sub to the loader at Ligon representing the end of the Long Fork. The E&BV, after wrapping under Price, emerges on the inside of the peninsula at Porter Jct. where the Jones Fork split from the main. The large flood loader on the branch is included, along with then engine house for its “mine critter,” but the tail tracks are hidden under Ligon to save space (I elevated a road crossing to a bridge to make the transition through the backdrop less obvious). Back on the E&BV main, the line runs through Lackey before diving under Stinson (there was a long open running space on the prototype) to emerge at Jim, the junction to Stinton. After traversing several feet through Raven, the line again ducks under Stinton to re-emerge around the corner with the load tracks for the enormous loader (actually a big loader and a smaller one, both belonging to the same operation). This reversing act allows the scene to be modeled closer to prototype, and it make the branch seem longer (which it was). The most significant compression occurs on the E&BV main between Jim and Kite, 10 miles of single track on the prototype.

Upper Level

After passing a few small loaders at Kite and Supreme, the layout includes a model of one of the two tall trestles near Hall, modeled near scale length and height and the first scene you see when entering the room (note the lack of scenery on the lower deck in this area). After crossing the trestle, the line enters a workshop in the back room and helixes down to the final scene at Deane, KY where the C&O meets the L&N to serve three good sized loaders. Deane was a narrow, long and somewhat complex track arrangement, most of which is represented here at a sufficient size to load full trains at the Rapid Load and Democrat loaders. From Democrat, the L&N ducks into a tunnel (again prototypical though moved up a little) to head down to staging.

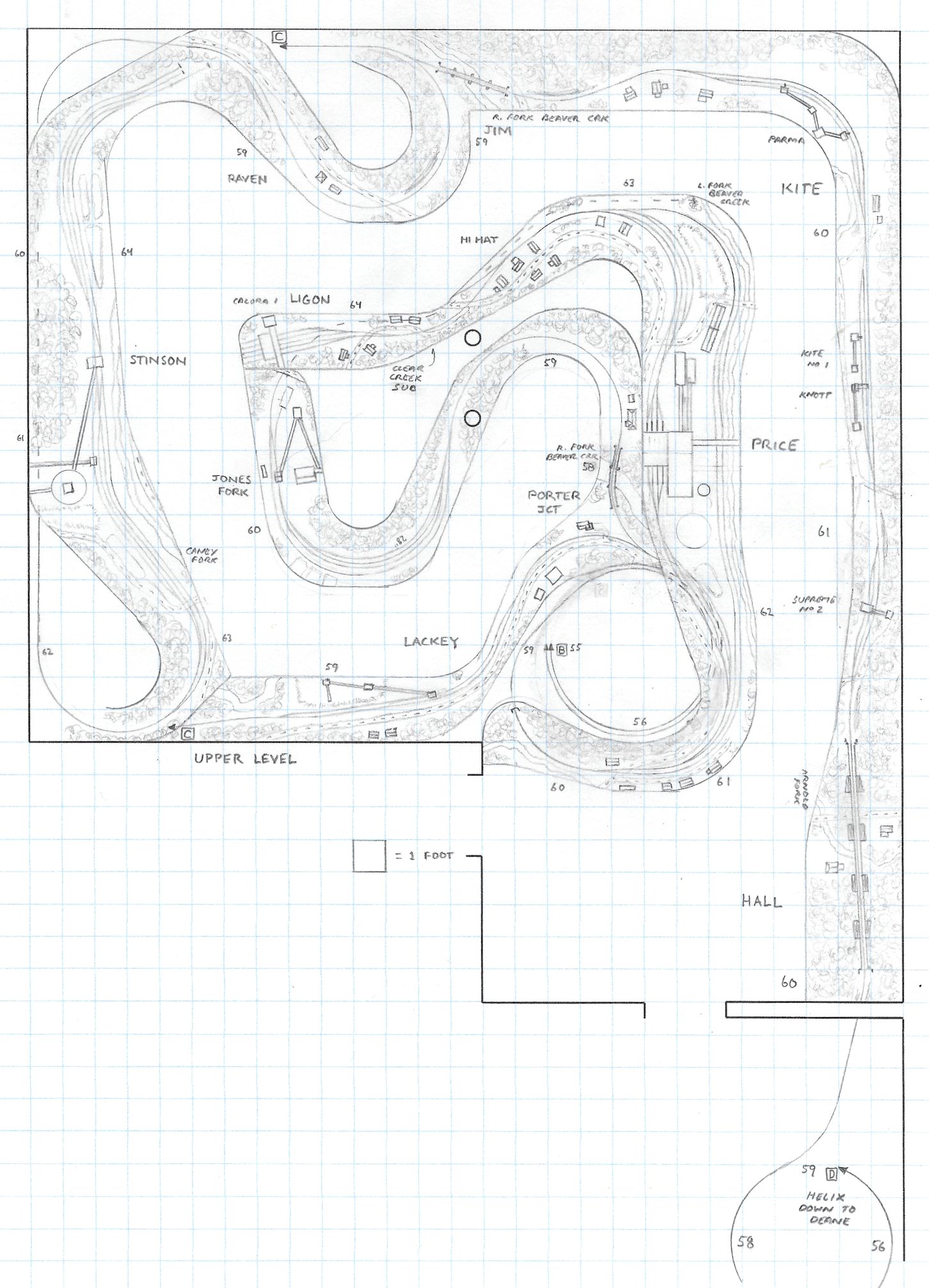

Staging Level

The staging level includes two double-ended yards. L&N staging is 4 tracks of at least 16 feet representing Hazard, KY–this yard, along the back wall, is elevated 2 inches over the C&O for easier access and viewing. The C&O’s yard, representing Paintsville, KY, is 10 tracks of at least 18 feet. A loop under the main helix connects both yards and forms a continuous running loop, and a crossover is included to perform reversing, if needed. I’ve also drawn a wye off of the loop to show where additional staging might be built, if desired (you could also build a long staging yard under Deane).

This is a lot of railroad, so running it would require a heavy duty DCC system with multiple boosters. Walk-around throttles are a must, and with the long run and snaky peninsula, wireless throttles would be very helpful. Construction wouldn’t be as complex as it seems. I’ve drawn several short stud walls on the lower level which should be more than adequate to hold up both the lower- and upper-level benchwork. The rest of the layout is easily supported by the wall and helixes.

Operations

As you might imagine, this layout could keep several operators busy for hours, but remarkably, it could also be run one train at a time by a single operator without major changes to the operations. Like most coal-hauling lines, operations mainly consist of mine runs working loaders in an out-and-back fashion. In this case, up to a dozen “shifters” (C&O speak for mine run) would operate out of Martin, serving anywhere from 1-4 loaders based on the tipple size. For a full session with multiple operators, a dispatcher would be needed to make sure each shifter had its own area to work without interfering with others. Even the large loaders at Jones Fork, Stinson and Deane Rapid Load were worked by dropping off empties and picking up loads rather than keeping the same cars and power together. Making the shifter work more interesting, three of the operations – Stinson, Spurlock (Salisbury) and Price – were prep plants that received raw coal in. The big loader at Jones Fork originally loaded only raw coal for Stinson before being rated as a flood loader around 1983. Stinson also received raw coal from some of the smaller loaders on the E&BV. Spurlock took raw coal from the Knott and Kite 1 loaders at times, and Price received raw coal from small loaders on the Long Fork Sub (thanks to Appalachian coal history expert Robby Vaughn for the information about the raw coal shipments and prep plants!).

A yard crew (1-2 operators) would bring long trains of empties up from Paintsville and trade them out for loads gathered in the yard (no need for road crews to work such short runs). Empties in the yard would be blocked for each shifter, power added, and the shifter dispatched. Returning shifters would drop their loads for the yard crew to classify with potentially some of the coal heading to the L&N instead of the C&O (the C&O could run it all the way to Hazard staging). An L&N crew could also be called to work the Democrat/Deane area and to run an occasional train through to Martin or even Paintsville. Finally, if there are extra operators, they could work the “mine critters” at Jones Fork, Stinson, Price and Democrat (there may be others) pulling empties and dropping in loads for the next shifter.

Variety could be easily gained by activating and idling loaders to change the business of the session and changing up the territory worked by each shifter. Variety could also be gained by changing the amount of run-through traffic between the C&O and L&N to include, perhaps, some non-coal traffic. If you’re in the mood for more motive-power variety, you could fast forward to early CSX when most of the loaders were still active but the hoppers and locomotives were starting to be mixed.

Things I Like About This Plan:

- Tons of loaders!

- Captures major elements of two long branches

- Some great scenic elements (tall trestle) in addition to the loaders

- Generous aisles for lots of operators–only a few 30″ pinch points

- Option for continuous running

Things I Don’t Like About This Plan:

- Some scenes are tough to reach

- Lots of hidden track in helixes and under Stinton

- Three helixes (three!!!)

- Some significant compression

Related Products:

A couple of comments. According to “B&O Power” by Lawrence Sagle, the E&BV was originally a B&O “project”, for lack of a better word. along with a pair of others whose names I don’t recall. Imagine backdating this to the early 20’s, with short hoppers and teakettle 2-8-0’s doing the mine runs! BTW, “shifter” is indeed a C&O term, Dad was an operator and later dispatcher who mostly worked the West Virginia lines on the then-Huntington Division. Many a time I heard him speak of the shifters going down the Coal River line to Logan and beyond.

Second, for obvious reasons, I need to see if any of my ancestors were involved in any of this! Years ago, an acquaintance told me how he knew the Spurlocks all came from Floyd County, KY. I’ve never been able to verify this but–hey, one never knows.

This plan isn’t for the faint of heart but I agree, this could be a labor of love with plenty of satisfaction for those who build it. Great job, Dan!

Dan, I made a mistake. The one B&O-sponsored line was the Sandy Valley and Elkhorn plus the other two (the names of which I don’t recall). Even so, seeing 2-8-0’s, 2-8-2’s, or some of C&O’s legion of 2-6-6-2 Mallets would be something else! Also, IIRC, they used Geeps from 7’s to 38’s on many of these lines. “Trains” magazine some years back had a feature about the former line through Ajax, KY that was converted back to a trail or maybe a road. I don’t know enough about eastern KY to be dogmatic, but again, you designed a fantastic layout for a remarkable piece of the USA!

You had me wondering what the B&O was doing eyeing eastern Kentucky–thanks for clearing that up! Yes, I wonder if your family had any connection to the Spurlock Spur on the Long Fork Sub…

I have a 1915 Virginian track chart from the NWHS that shows the planned Virginian Kentucky extension out of Gilbert was supposed to meet the B&O at Shelby. Pretty crazy to think about!

Dan,

I’m a CA native, western modeler but these Appalachian plans are fascinating.

Pre covid we use to operate at this fellow’s layout near Santa Barbara who models the L&N EK division in his garage. AFAIK he’s the only guy around here who models Appalachain railroading and it’s quite the experience.

I’d venture to guess that about 80% of modelers here model either the SP or ATSF… or both (myself included).

Keep up the great work.

-Dean